Assembly production

Innovative CAD Design

Every assembly begins with thoughtful planning. Our experienced team uses state-of-the-art CAD software to develop customized solutions tailored precisely to your requirements. We take all relevant factors into account – from functionality and material selection to the optimal manufacturing strategy.

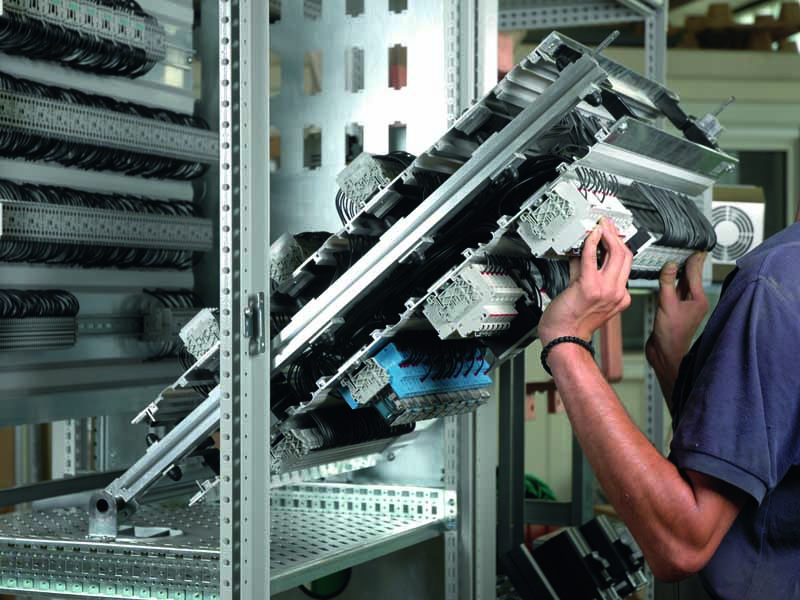

Assembly with Cutting-Edge Robotics

Efficiency and precision are our top priorities. Using highly advanced robotic systems, we ensure fast, reliable, and error-free assembly of your modules – whether in small batches or large-scale production. Where needed, we implement semi-automated processes that can be flexibly adapted to your individual needs.

Comprehensive Quality Control

Our quality standards are uncompromisingly high. Every assembly undergoes a thorough inspection process, during which we use advanced measuring technology and detailed control documentation to ensure that only flawless products leave our facility.

Material Procurement & Inventory Management

We think beyond production. A well-structured inventory management system ensures that you always have full control over your assemblies – enabling smooth logistics and reliable availability of your components.

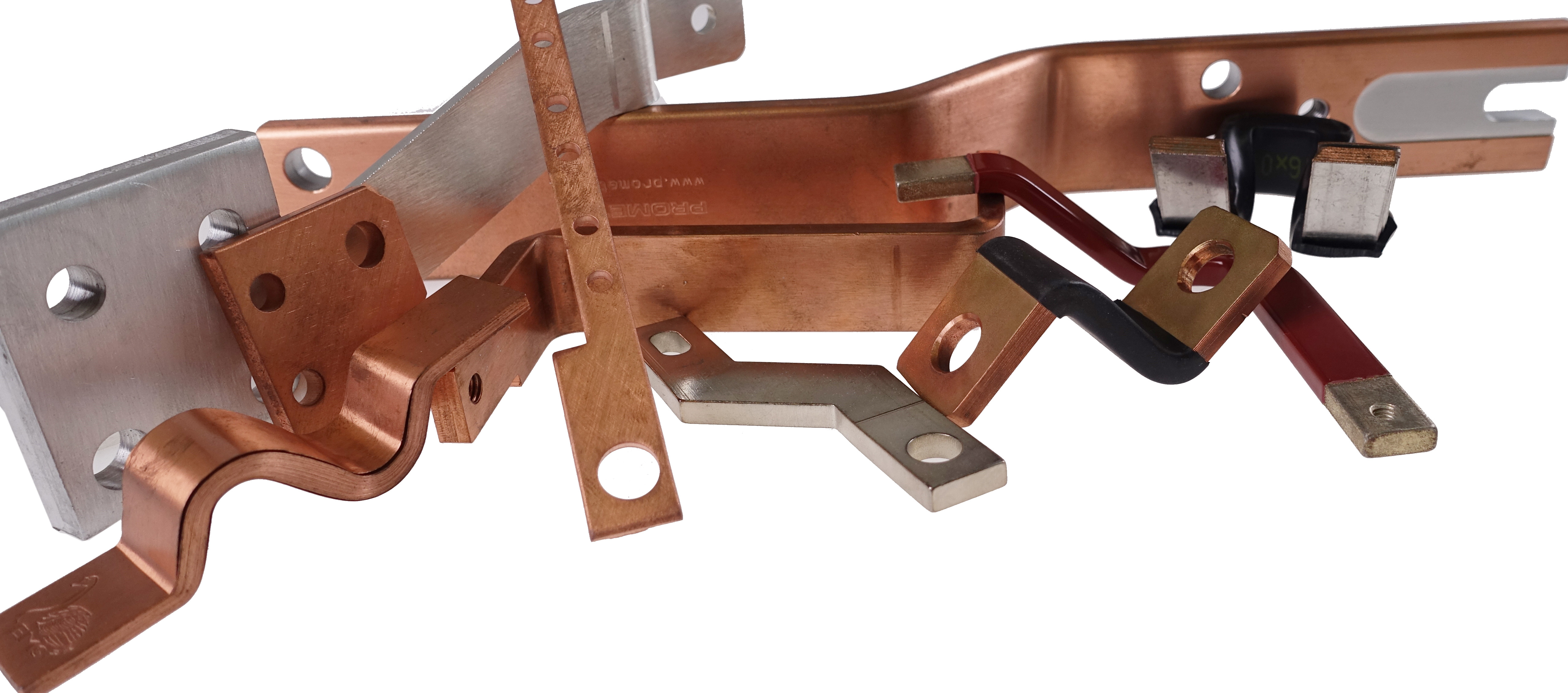

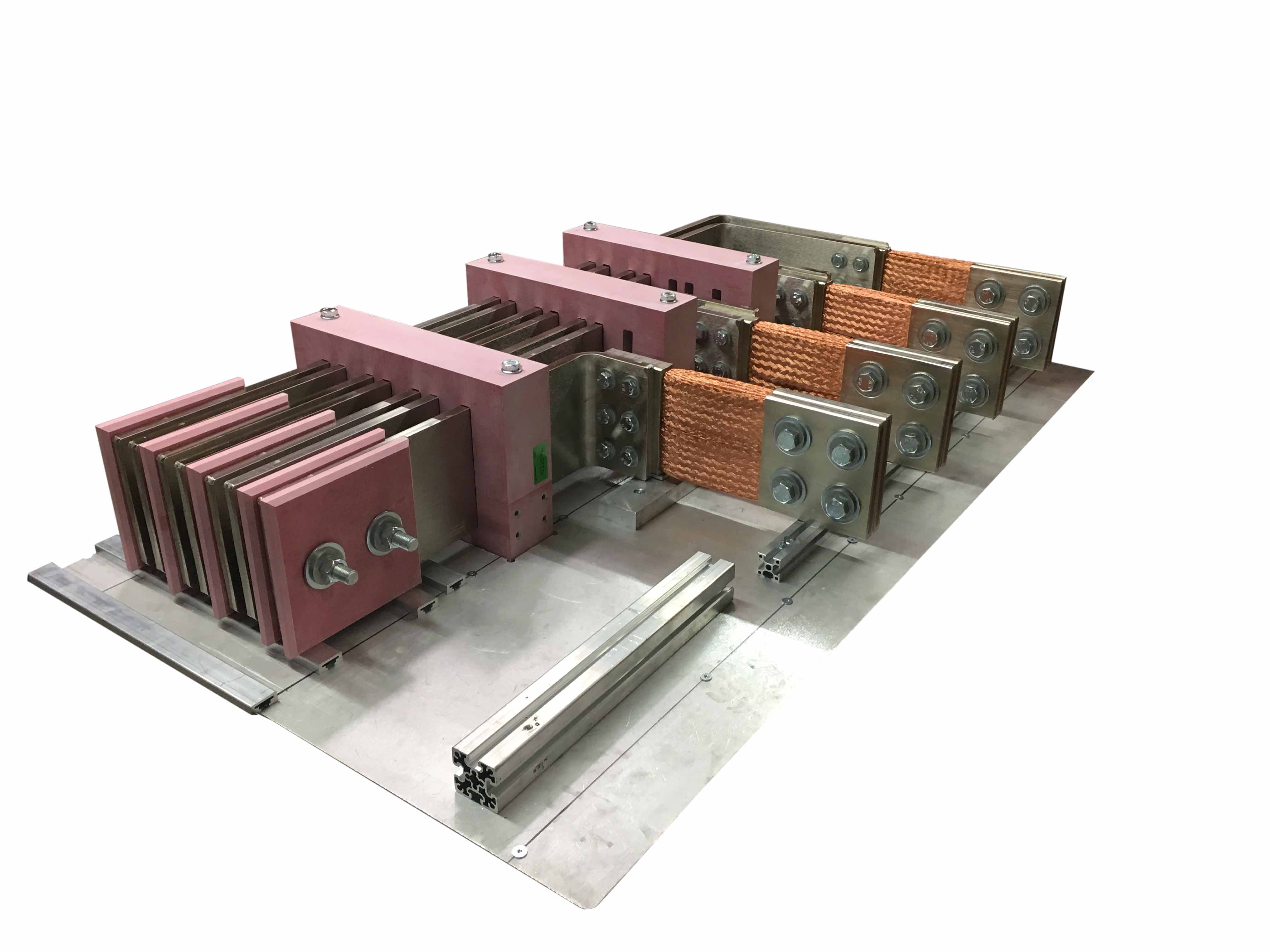

Flexible Manufacturing – From First Prototype to Large-Scale Production

Every product starts with an idea – we make it a reality. Whether it’s a single prototype for testing or mass production in large quantities, our flexible manufacturing system allows rapid adjustments to new requirements and scaling as needed. This way, we bring your innovation to market efficiently and reliably.

Custom Surface Finishing

Not only functional but also visually refined: On request, we offer professional coatings in any RAL or NCS color to give your assemblies the desired aesthetic and added protection.