Busbars

ZETKA supported its customers with prototypes and small series from the very first electrically powered vehicles.

The experience we have gained in this way gives us a knowledge advantage and enables us to ask the right questions in order to precisely determine customer needs.

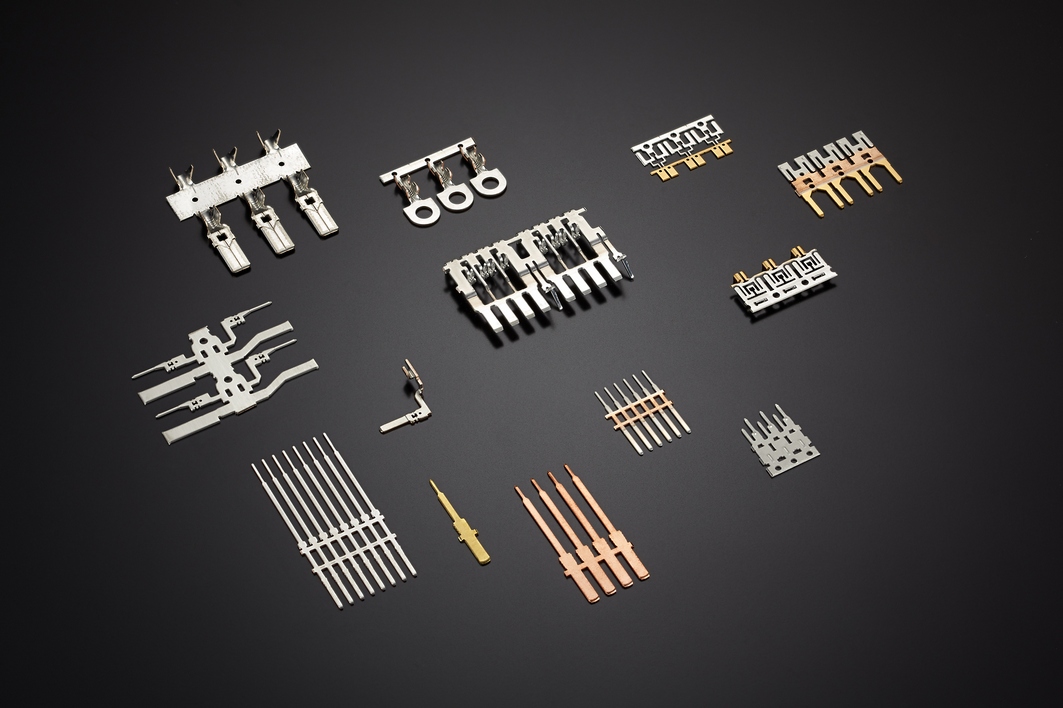

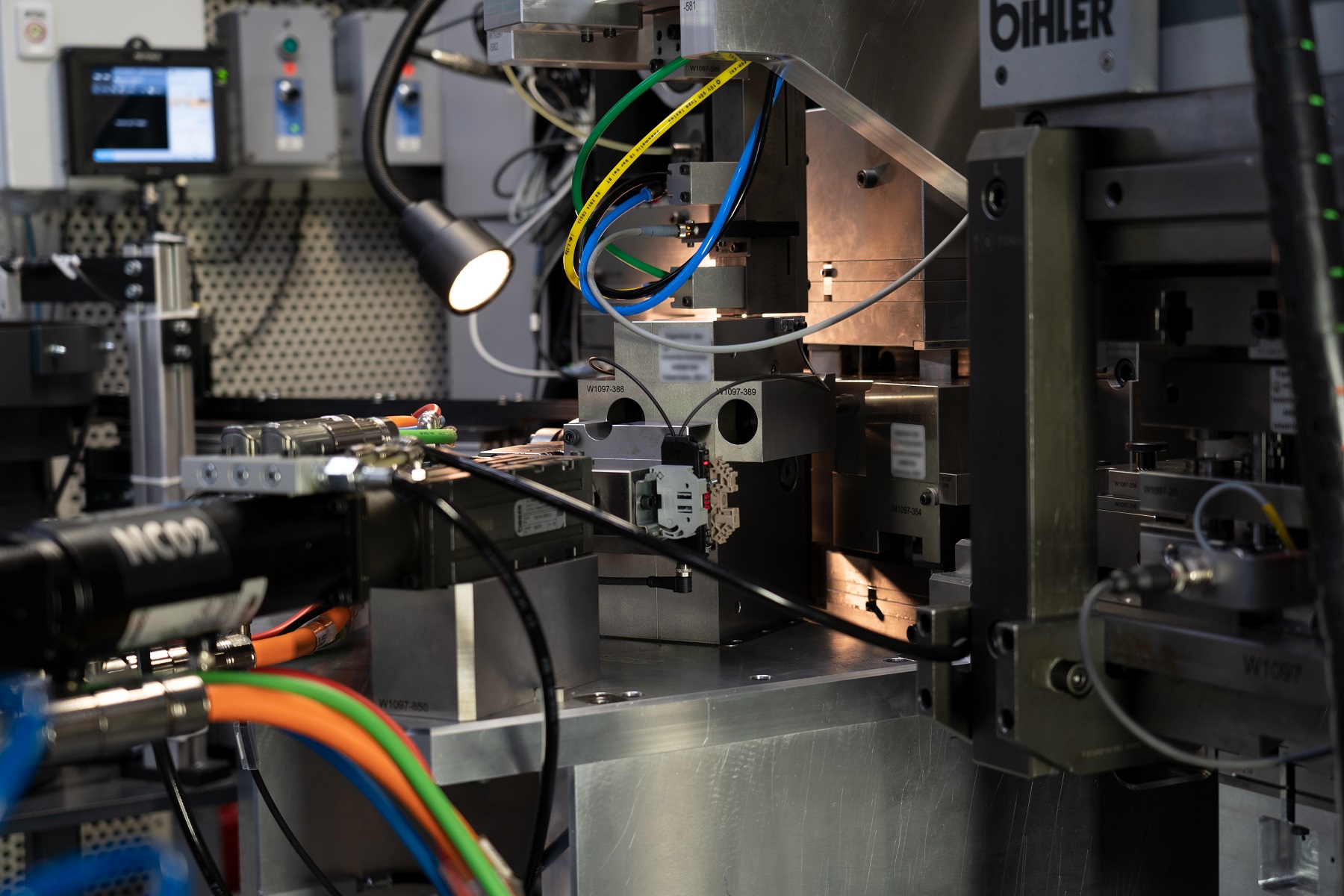

The use of special Lean-Tool stamping and bending tools for our Bihler GRM-NC system allows us to produce busbars with a material thickness of up to 4 mm in a cost-effective and material-saving manner, depending on the geometry.

We usually optimize these with our customers in order to achieve the highest possible process reliability. More complex busbars, on the other hand, are manufactured on our stamping machines using modular progressive dies.

With both production concepts, we are able to produce both small series and large series.

In the development process, however, laser or micro water jet cut prototypes or pre-series are used. The completion with press-in threaded bolts or press-in nuts as well as the use of insulating foils or hoses usually takes place in a subsequent operation, independent of the stamping process. This also allows us to carry out mechanical or galvanic post-treatment.

For optimal further processing, we use product-specific blister packs or deliver the parts as tapes, as long as the material thickness allows.

The materials used are sourced exclusively from European plants. If necessary and required, the material is pre-processed or the individual parts are treated using frame electroplating.