Your vision. Our capabilities. Products for the world of tomorrow.

Our innovation:

Shaping visionary ideas. Finding new solutions. Producing high-tech components.

For more than 30 years, LCP has been your specialist for the laser processing of filigree, geometrically complex and sensitive fine and micro-precision components made of metallic and hard-brittle special materials. Our technical expertise, our R&D activities as well as the passion and creativity of our team drive us to produce new solutions for high-performance products in demanding high-tech applications.

Our performance:

Good individual advice. Achieving high precision. Enabling excellent functionality.

LCP stands for precision in manufacturing, reliability in quality and speed in delivery. Our service along the entire process chain is the basis for the satisfaction of our customers worldwide. We manufacture your drawing parts with high accuracy of fit and efficiency, long durability and safety. The particularly gentle processing of components is our great strength.

Our diversity:

Using smart technologies. Integrating broad expertise. Serving sensitive industries.

LCP guarantees you high availability of many material specifications and flexible production with a wide range of laser processing methods. Advice on technical feasibility and reliable manufacturing processes make LCP a first-class implementation partner for sophisticated product ideas for industries such as:

- Sensors & Systems

- Power Electronics

- E-mobility & energy

- Precision mechanics and apparatus engineering

LCP: Inspire customers. With laser power.

-> Be ahead. With us.

Our laser processing methods at a glance:

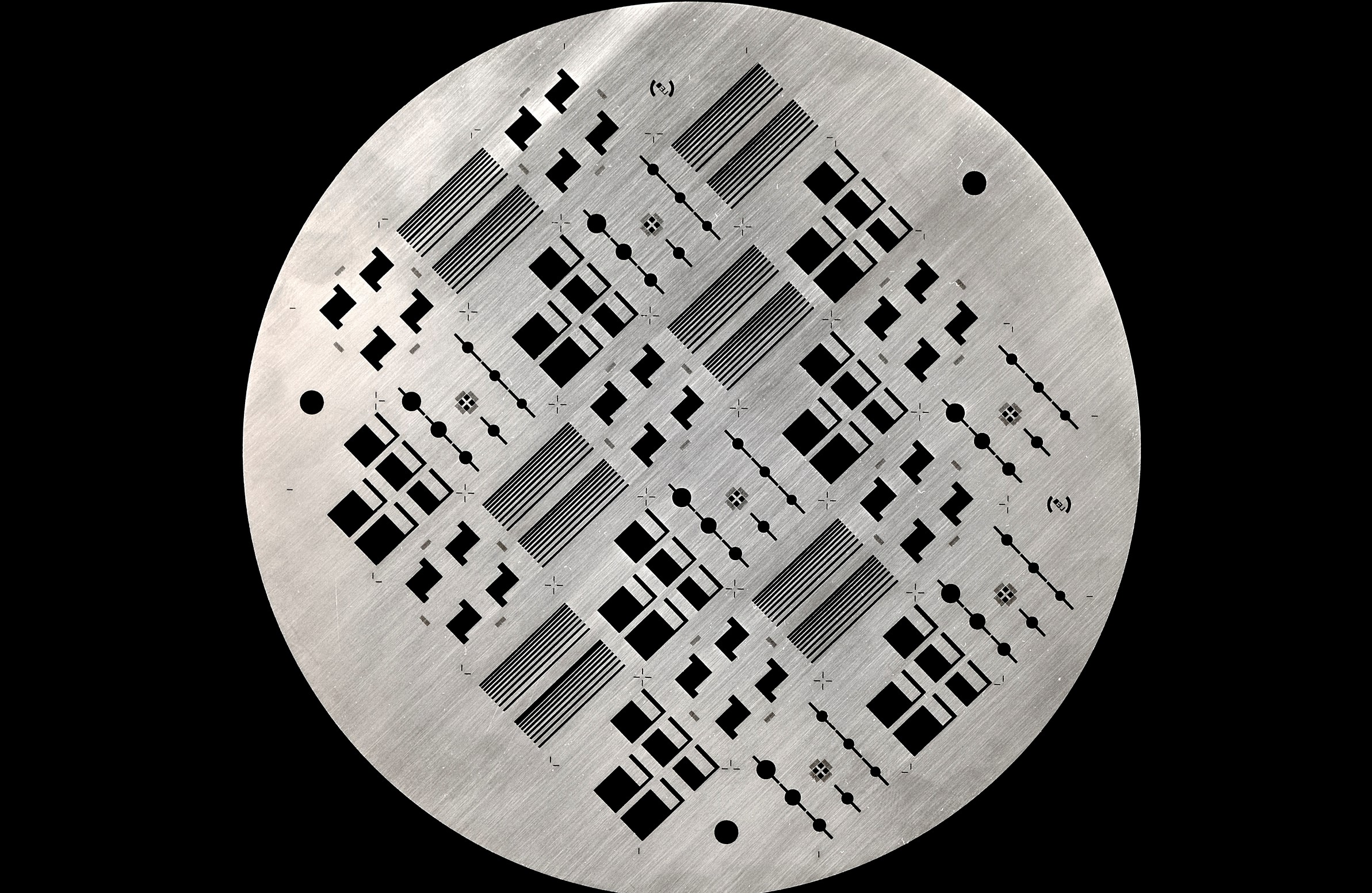

- Laser fine cutting

- Laser fine welding

- Laser structuring

- Laser drilling

- Laser scribing

- Laser marking

Further (re)processing options at the glance:

- wafer dicing

- mechanics (turning, milling)

- precision bending

- vibratory grinding

- glass bead blasting

- order measurement

Range of materials at a glance:

- High-performance ceramics (Al2O3, AlN, SiC, SiN, 3YSZ)

- Glass and silicon wafers

- Printed circuit board material

- Non-ferrous metals

- Refractory metals

- High-performance plastics

- Foils

We manufacture and/or process according to customer requirements, among others:

- ceramic substrates, fillers, bases and other ceramic components

- printed circuit boards (rigid/flexible)

- micro screens, grids, filters

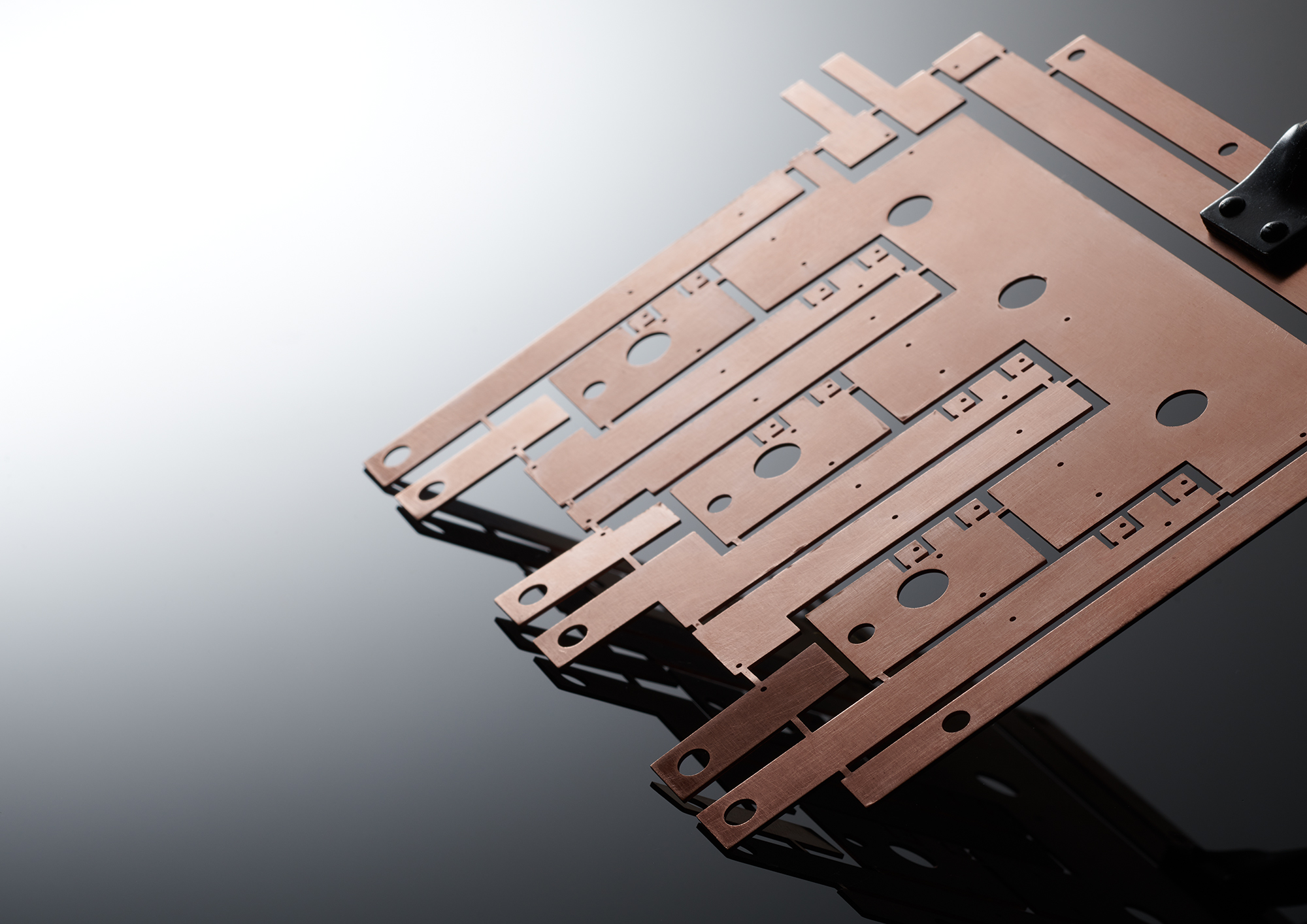

- busbars, leadframes, flat contacts, contact springs, contact bridges, connectors, single pins, injection molded inserts

- sensor housings, EVM housings, covers

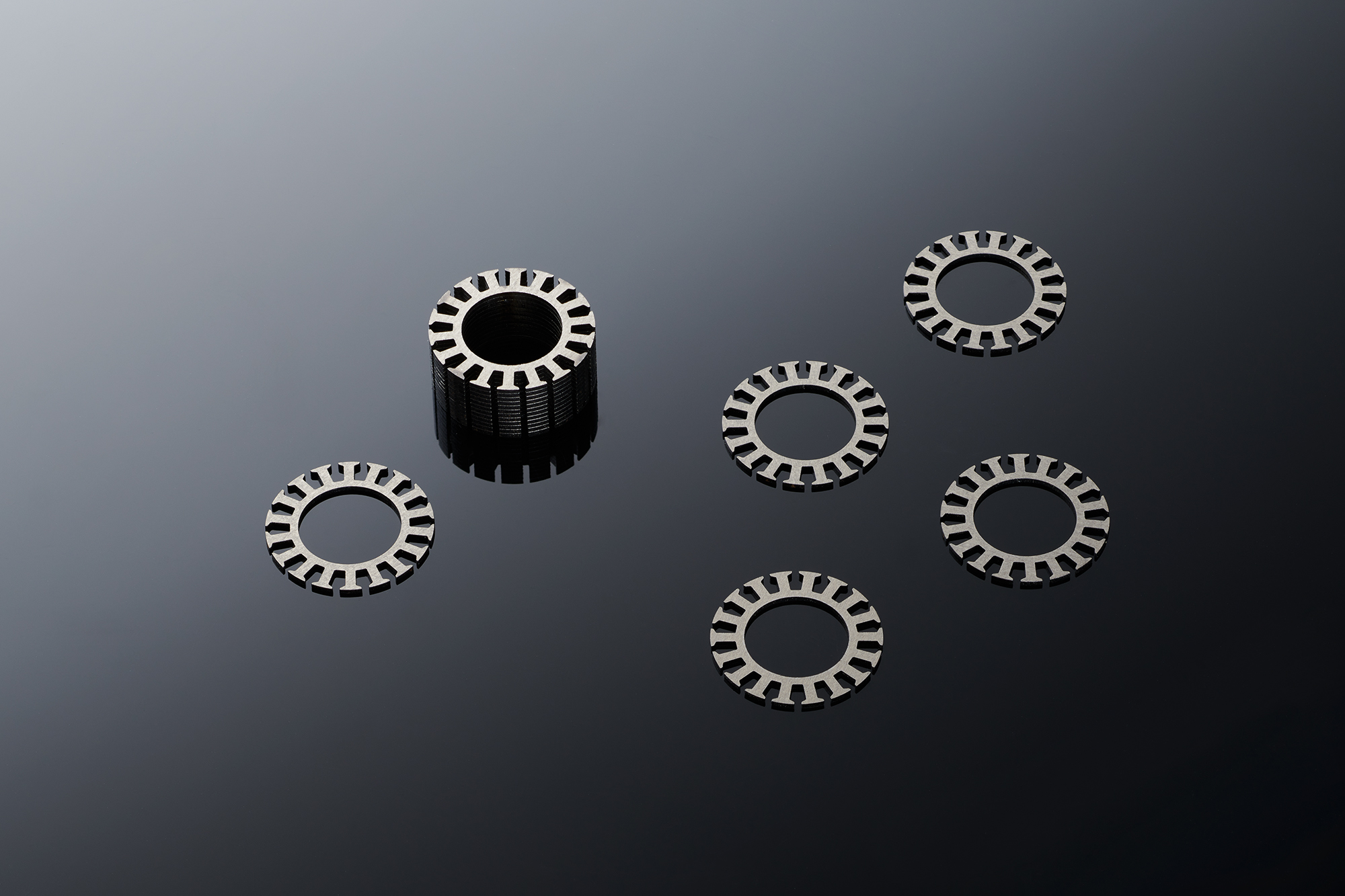

- rotor/stator laminations and stacks

- dies, fixture construction

Additional services at the glance:

- consulting + intensive process support (sampling)

- pure material procurement (also without machining, smallest quantities, special materials)

- order measurement, component cleaning

- research & development (joint projects, process development)

- extensive network of cooperation partners (surface finishing, alternative machining processes, etc.)

You can find detailed information at http://www.lcpgmbh.de.