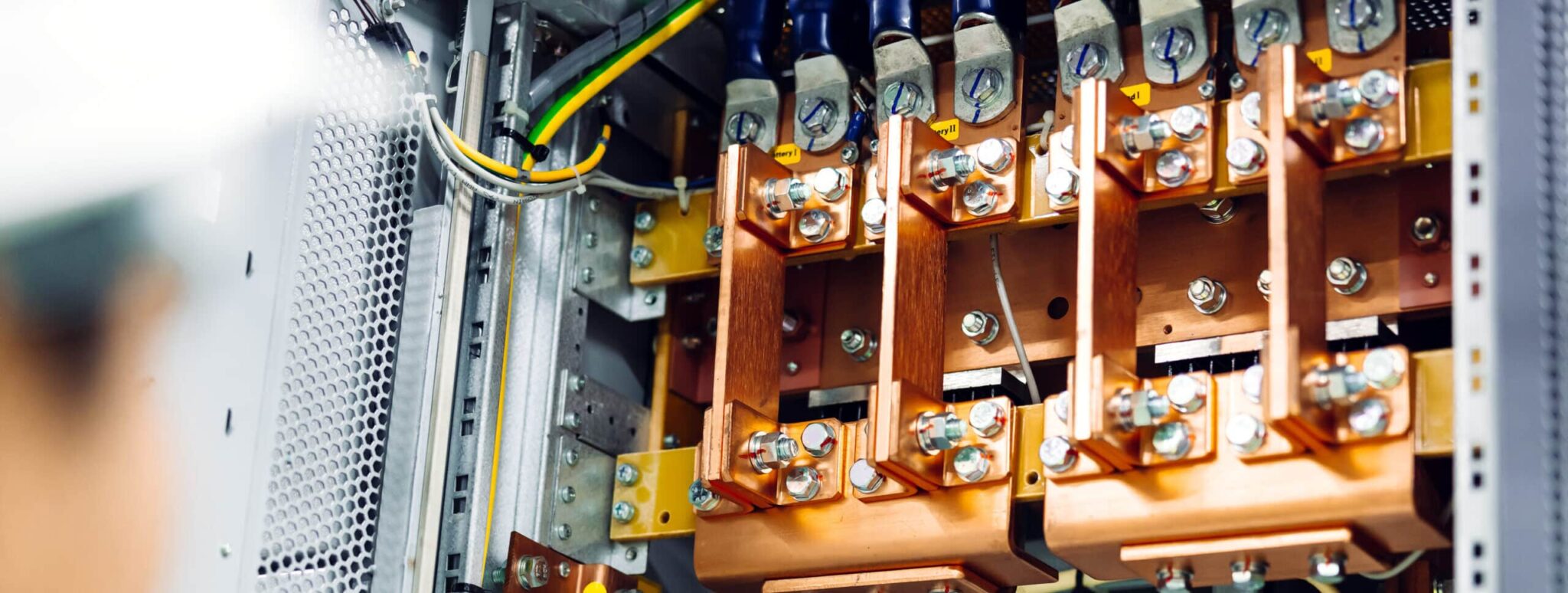

Thanks to our factory in Germany, we give our customers access to a wider range of products. We manufacture near Düsseldorf using a multi-step process that combines drawing, rolling, and annealing to produce a wide range of flat and round wires in small sections. Typically custom-made to meet client specifications, our production capabilities also allow us to manufacture this range in various shapes (rectangular, square, round, hexagonal), different sections/dimensions, and with surface treatments such as silver plating or tinning. We support our clients in markets such as automotive, grounding, and electrical equipment.

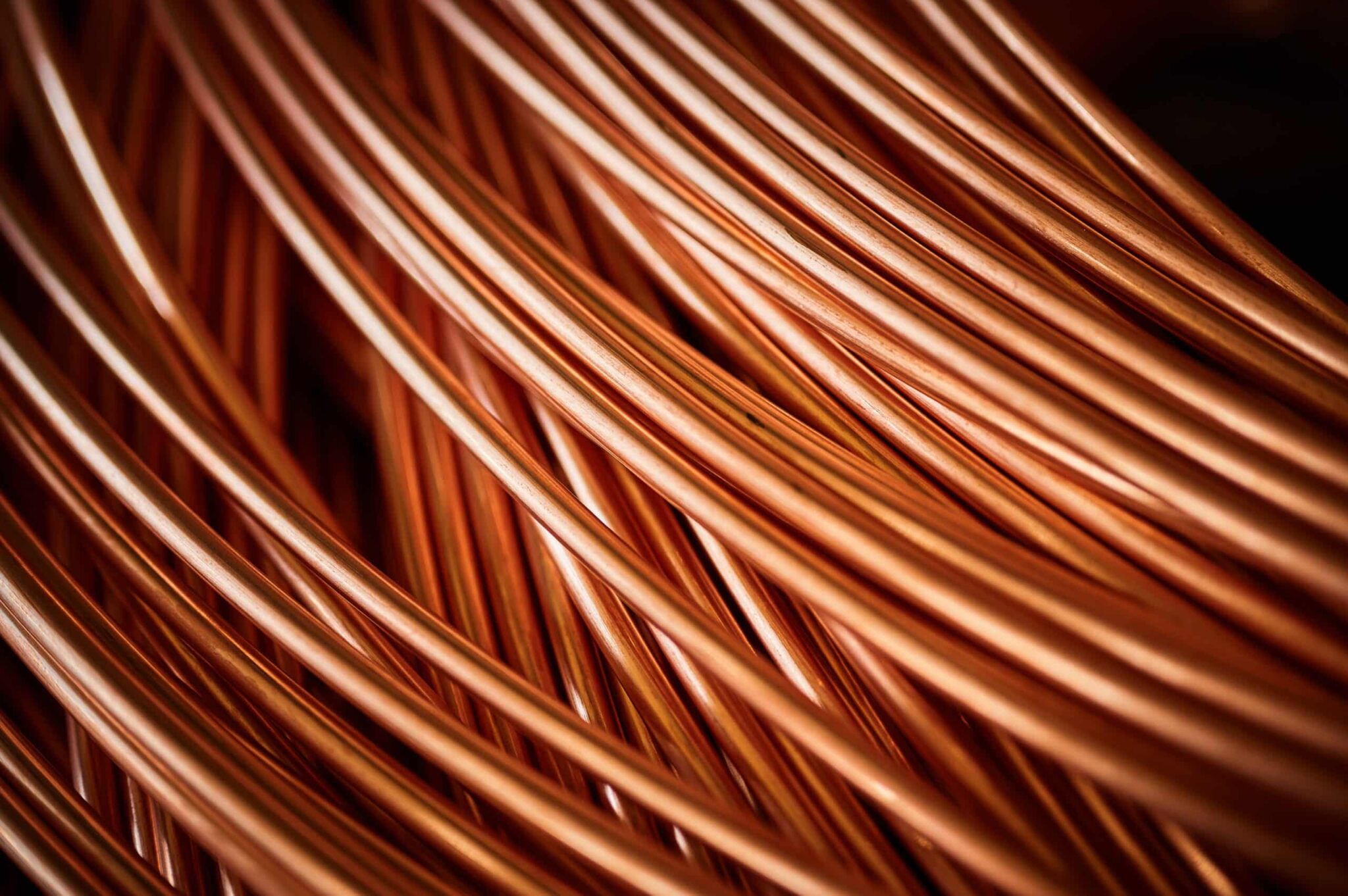

ROUND WIRES IN BUNDLES :

Diameters from 4 to 10mm.

Internal boot diameters : 400 and 500mm.

Boot outside diameters : from 800 to 1200mm.

Boot width : if inside diameter 400mm then width from 250 to 300mm. If inside diameter 500mm then width 250mm only.

SQUARE AND HEXAGONAL WIRES :

On request.

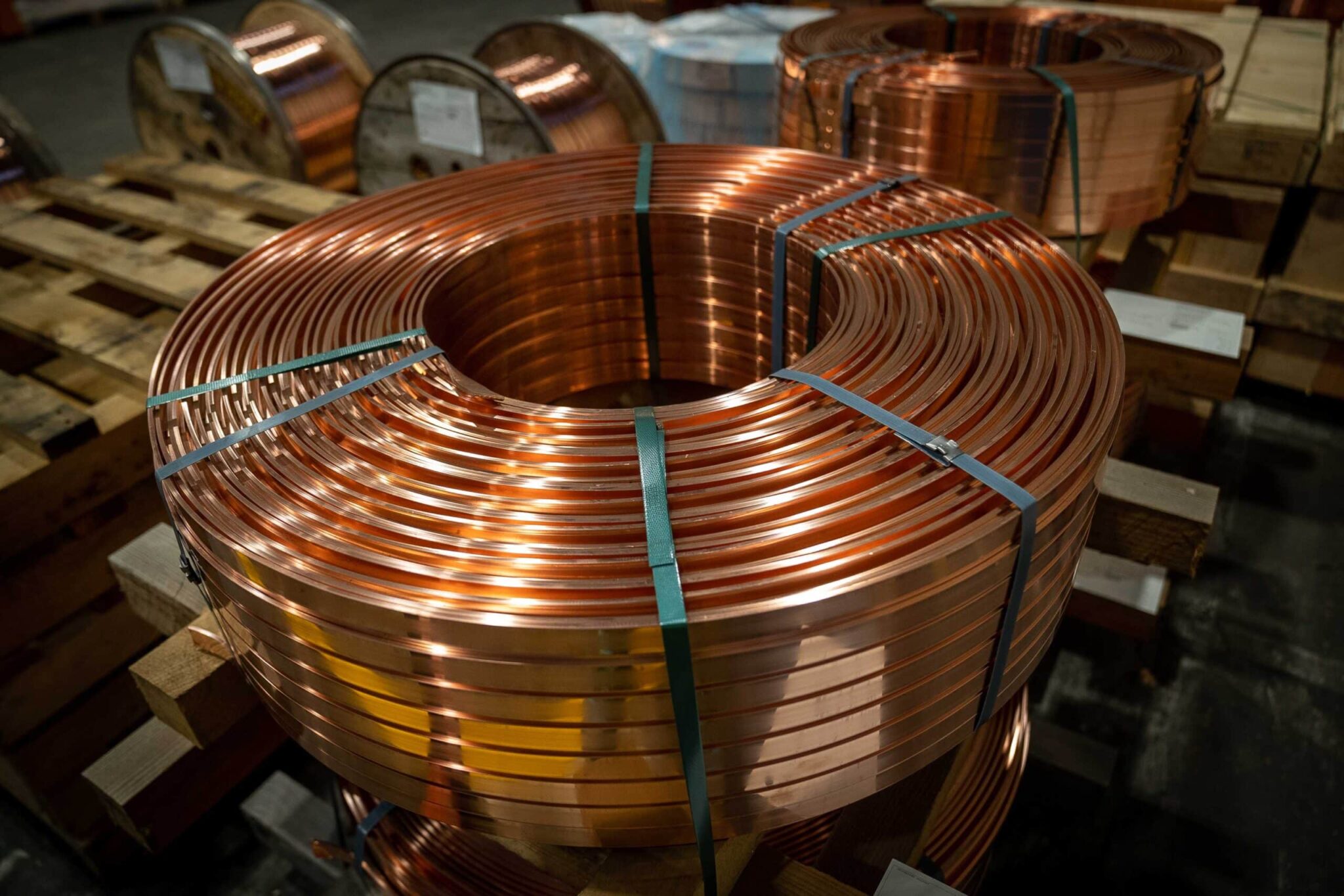

FLATS IN BOOTS:

Widths from 10 to 32mm.

Thicknesses from 2 to 7mm.

Sections up to 200mm².

Internal boot diameters : 400 and 500mm.

Boot outside diameters : from 800 to 1200mm.

Boot width If inside diameter 400mm then width from 250 to 300mm. If inside diameter 500mm then width 250mm only.

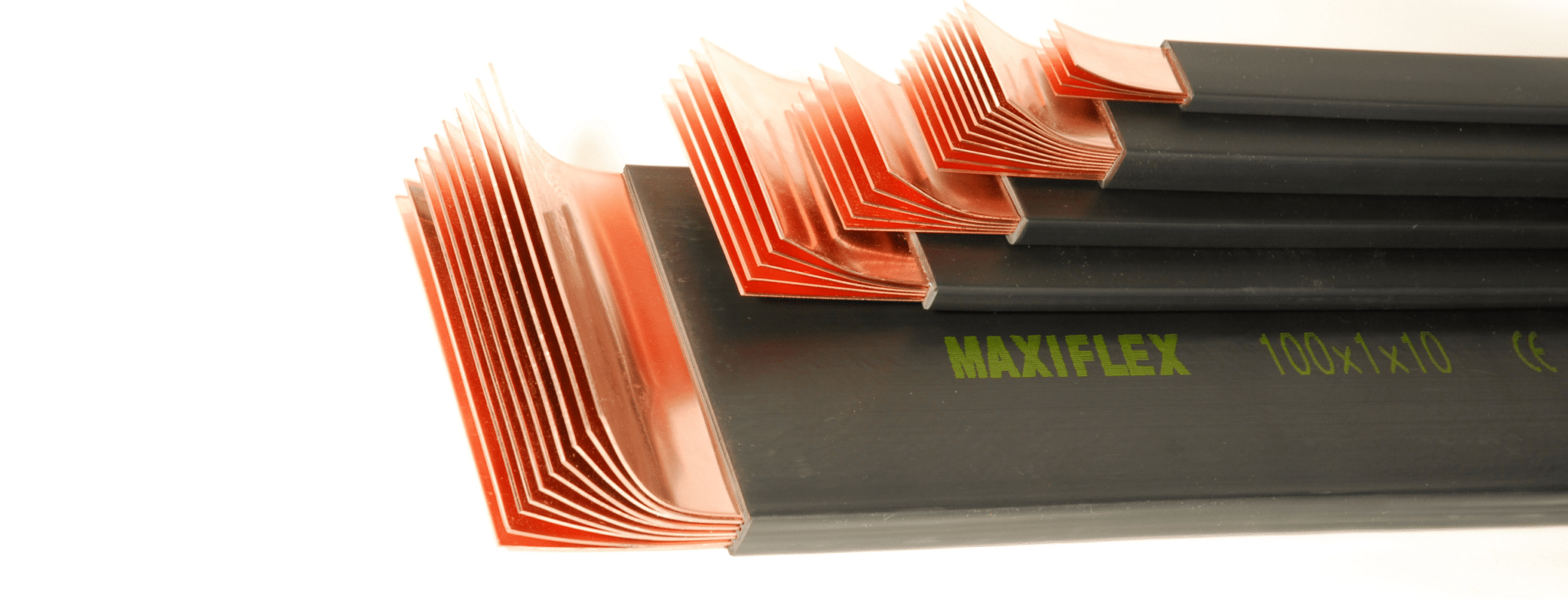

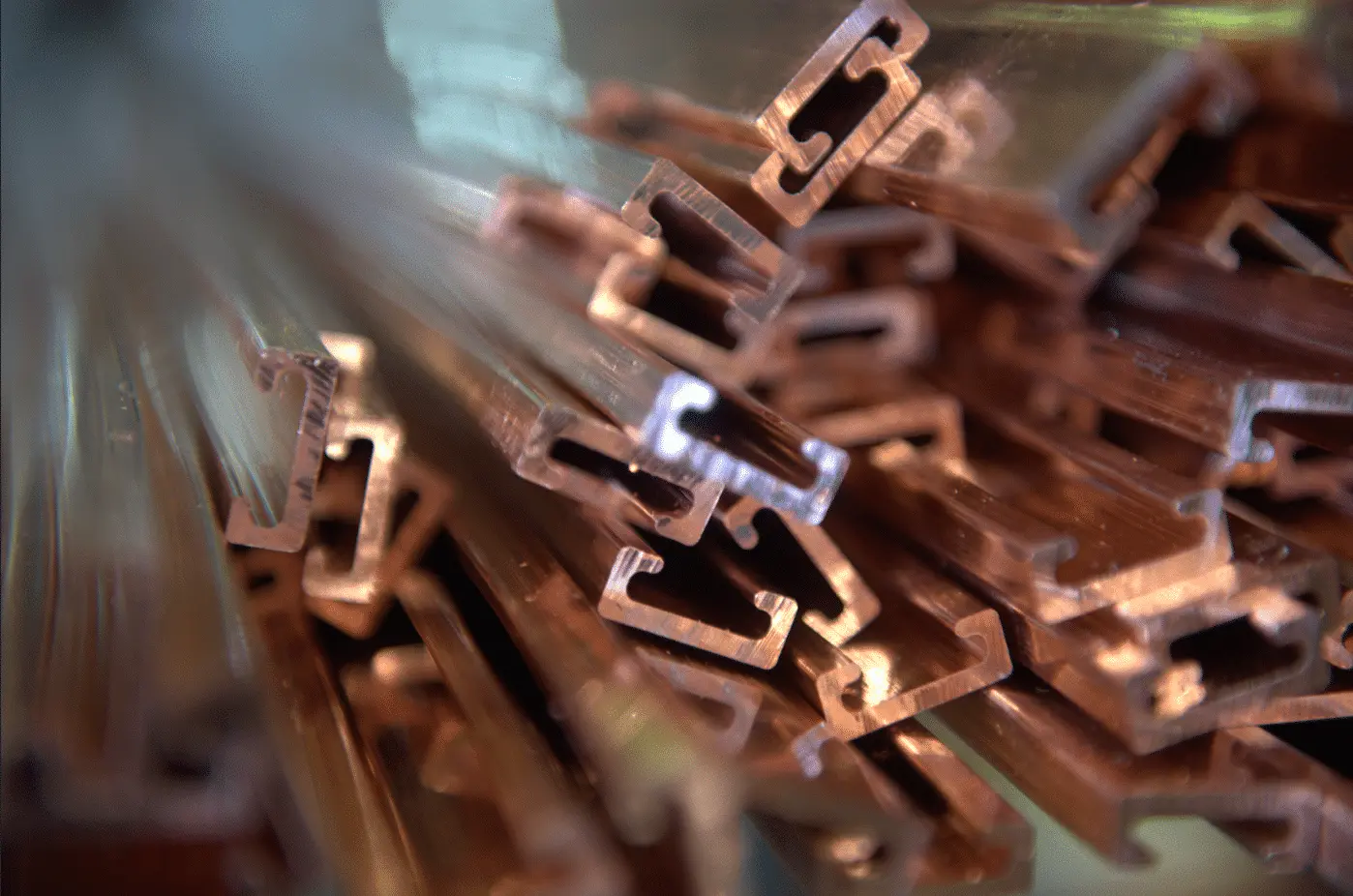

FLAT ROLLED PRODUCTS :

Widths from 25 to 200mm.

Épaisseurs : de 2.5 à 8mm. (< 2,5 mm et > 8mm, sur étude)

Cross-sections up to 1440mm².

Roll inner diameters : 400, 500 or 550mm.

Roll outside diameters : up to 1200mm (1300 without annealing).

FLATS STRETCHED INTO ROLLS :

Widths from 20 to 120mm.

Thicknesses from 2 to 10mm.

Cross-sections up to 1440mm².

Roll diameters (inside and outside) : to be studied according to product section.