A digital twin to detect disparities

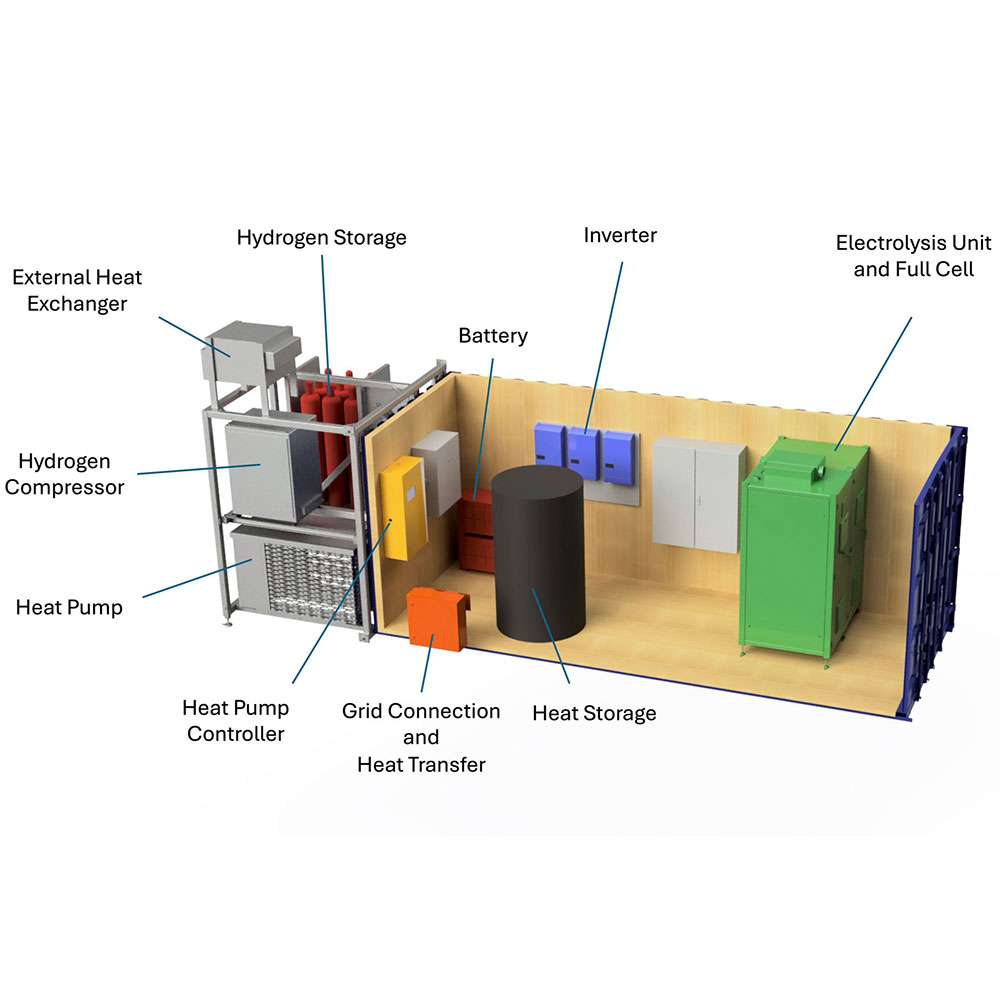

The Institute of Electrical Machines (IEM), at the RWTH Aachen, is developing a monitoring system that can be applied to determine the changing insulation condition of motors. The approach combines data from electrical sen-sors and sophisticated modelling, to predict faults before they impact operation.

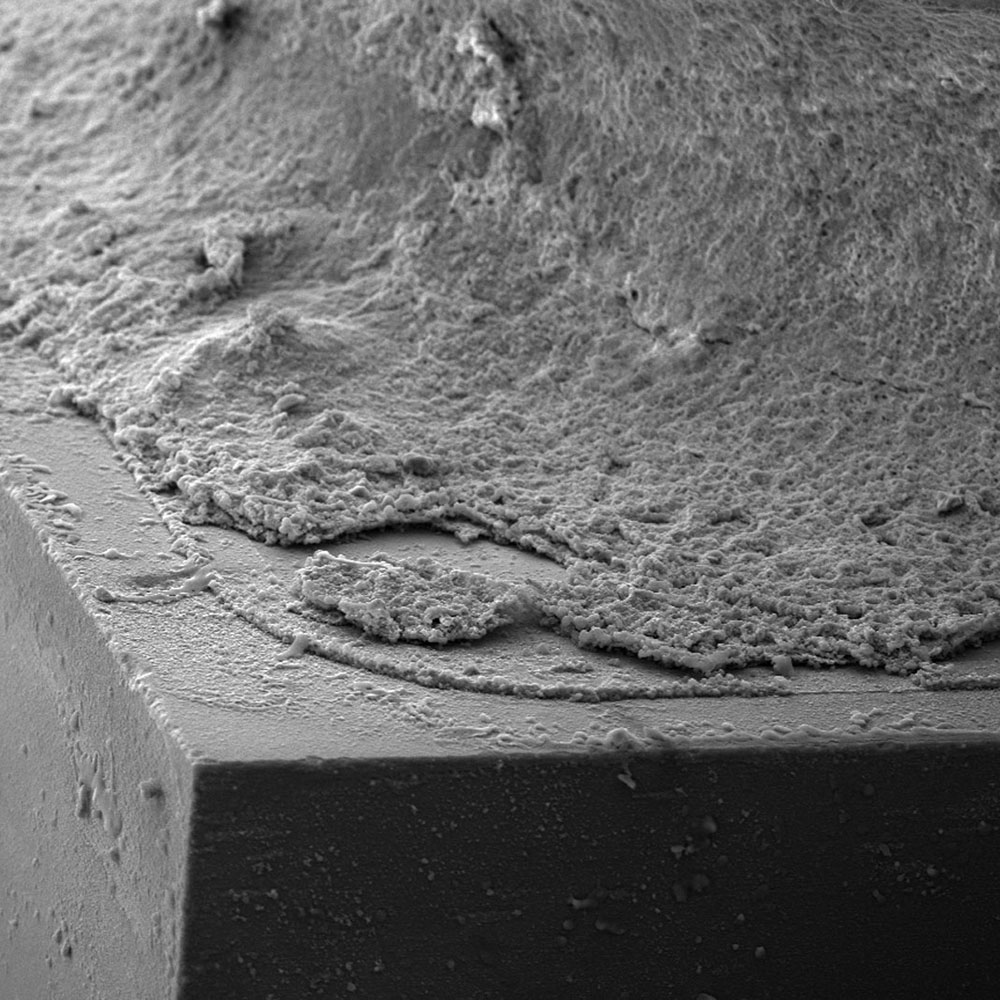

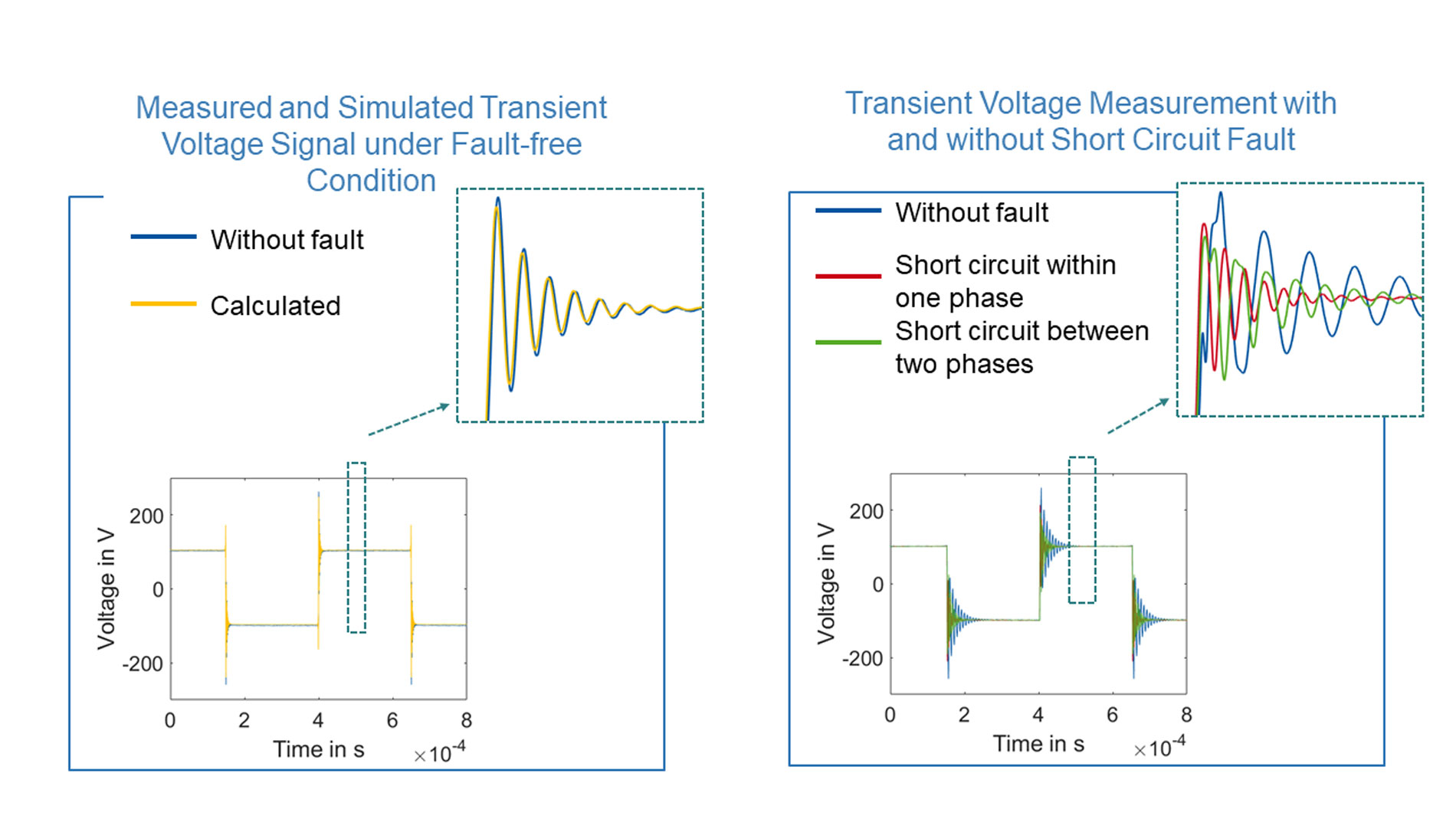

The digital twin applies high frequency modelling technologies to calculate the expected common-mode current, based on the voltage signals measured. The simulated current (which represents fault free conditions) is then compared with a real-time measurement. The disparity between the simulated and measured transient behaviours during switching show alterations in the parasitic capacitances that indicate stator winding deterioration.

Validated insights

Experimental data has validated the high accuracy of the simulated transient signals, and the sensitivity of the system for effective, real time detection of even small changes. The trend of the disparities between the simulated values and the measured voltage and current signals provide valuable insights into thermal and electrical aging processes, and make it possible to proactively avoid device failure.