Density, efficiency, reliability

Getting to the limits of any power system, in terms of power density and efficiency, relies on having an accurate characterization with high confidence. The more uncertainty there is in this data, for example, the greater the thermal safety margins of an overall design need to be. Apart from performance this can also have repercus-sions for the acquisition and operation costs. Precise characterisation also opens the door for digital twins, facilitating the running of varied simulations, as has become more prevalent in power electronics development in recent years.

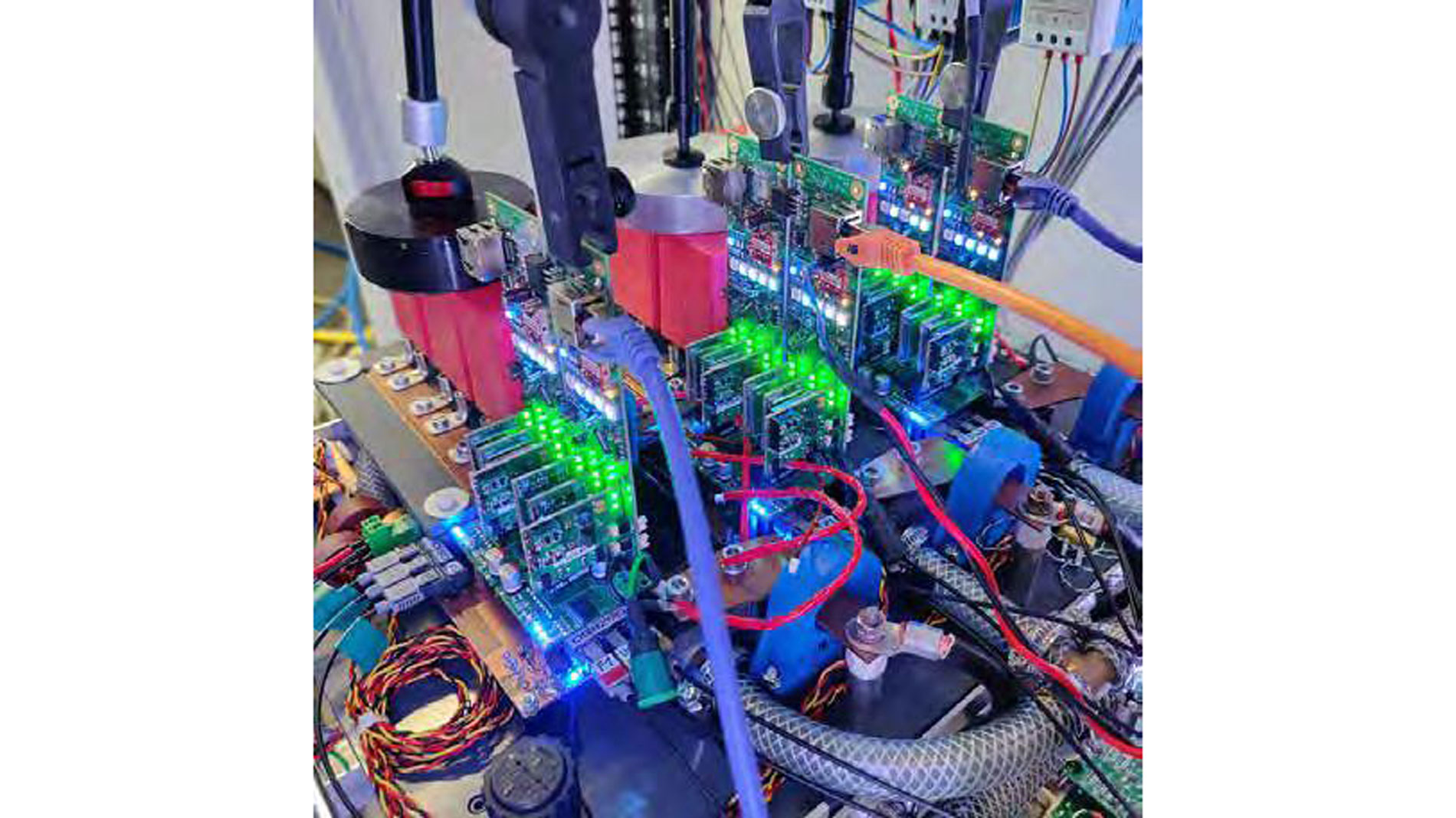

The higher densities of energy and currents, as well as the shift in assembly from bond wires to sintering, surface mounted and embedded components, as well as new packaging configurations, also increase the complexity of electrical and material interactions in new solutions. This all has potential implications for reliability. Given that, in applications from wind turbines to heavy vehicles, the power electronic components are expected to work for decades, the role of power cycling is more important, whilst becoming more complex at the same time.

The foundations for simulation

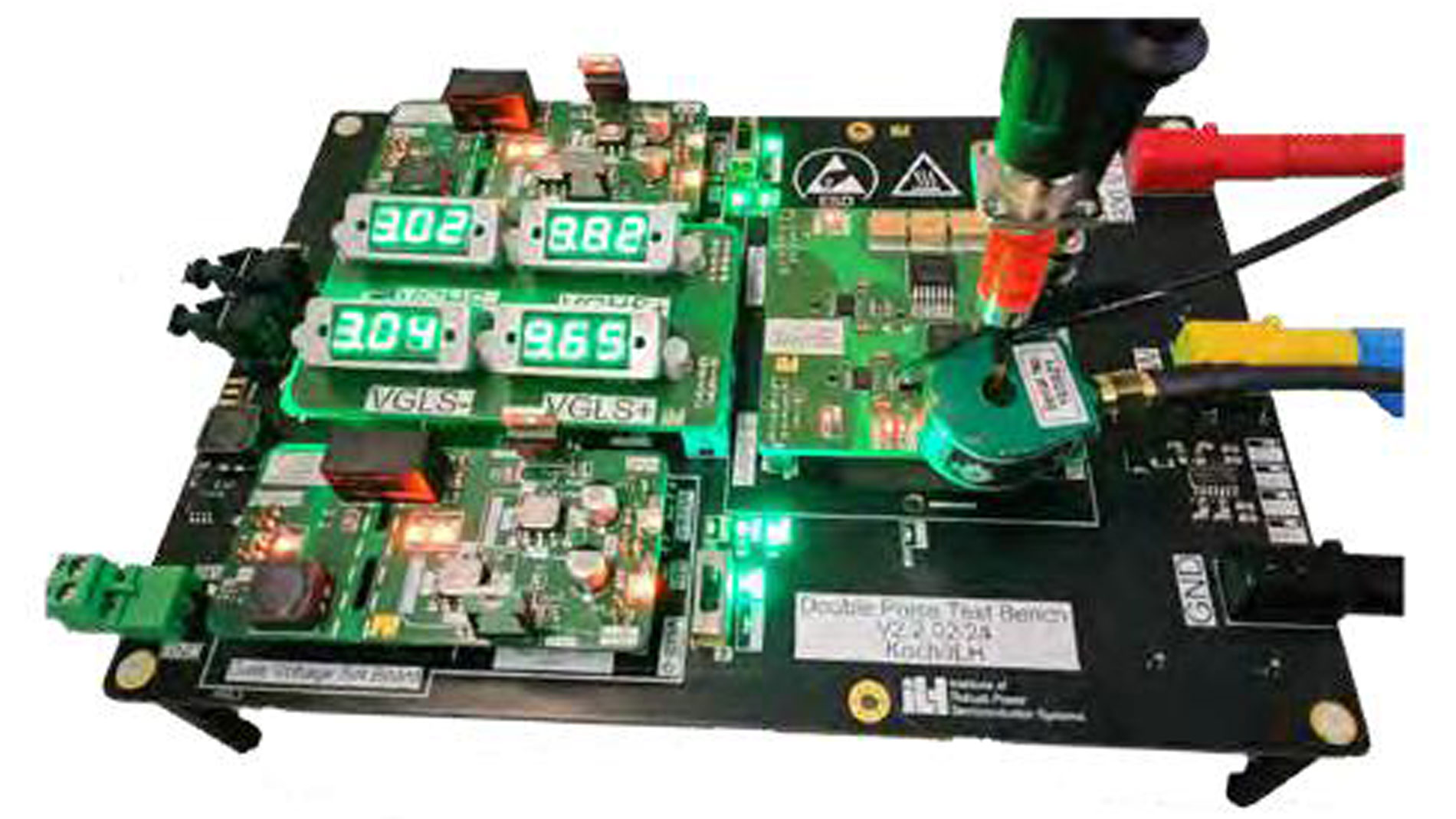

Compared to characterisation of silicon, the switching speeds of wide bandgap materials necessitate a rethinking of measurement methods to be sure of getting the required information. This starts with the equipment and setup. A double pulse test for silicon, for example, is easily done with bandwidths in the tens of MHz. However, this is insufficient for GaN, which is more than ten times faster than silicon, and has switching transients in the nanosecond range. Part of this challenge is being met by the advances in technology, for example, using optically isolated probes, or novel current sensor techniques, which promise very wide bandwidths. Beyond this evolution of the equipment, there is also a need to explore new measurement procedures. For example, characterising soft switching losses of SiC or GaN pushes beyond the envelope of practical electrical measure-ments: de-skew needs to be down to picosec-onds to differentiate the positive and negative currents. Instead, calorimetric measurements are in development, though these have chal-lenges, not least in the measurement duration.

An explosion of data points

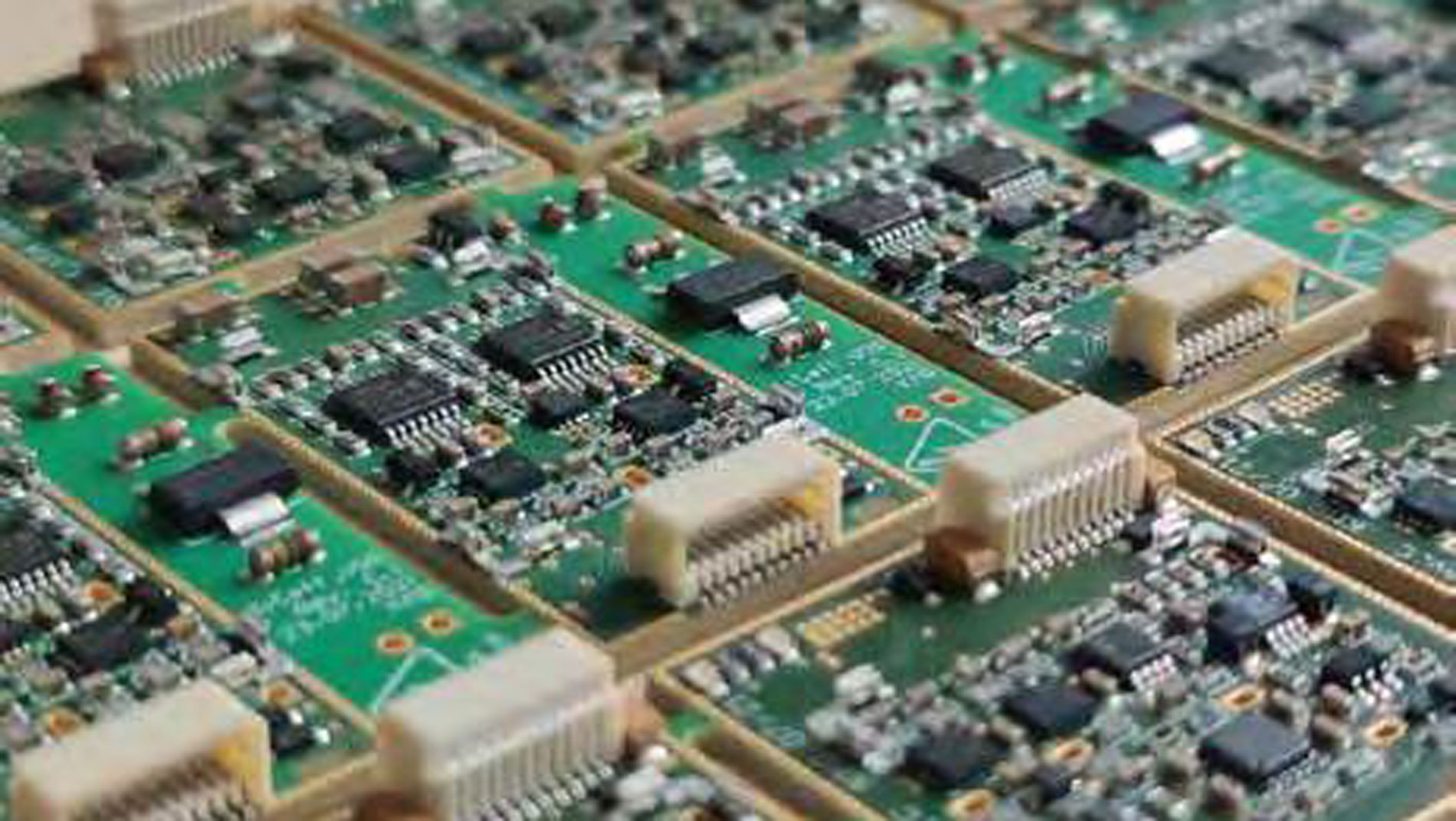

The higher bandwidth measurements, as well as new measurement procedures have resulted in a dramatic increase in the amount of measurement data. For example, for some power cycling tests, each of the many switching events produces six different, temperature-sensitive electrical parameters, using specially developed acquisition boards. These need to be analysed, to separate out the temperature and aging effects, as well as any measurement error. This would be possible with fitting functions. However, this is pre-cisely the kind of problem for which machine learning is well suited. AI can identify correla-tions that might otherwise go unnoticed – and there is potential for establishing correlations that might reduce the number of tests needed. On the other hand, sometimes working on an algorithmic approach benefits a fuller under-standing of the physical behaviour.