Dipl.-Ing. Christian Schöner, Business Development Manager Power Electronics and grid Integration Power Solutions, Fraunhofer Institute for Solar Energy Systems ISE

Co2 emissions must be significantly reduced by 2050. To achieve this, we need a big increase in renewables. For photovoltaic, an increase of around 73 TW in installed capacity alone is expected worldwide. additionally, the electricity, heating and mobility sectors will be electrified, with the electricity grid becoming the hub for sector coupling. Using today’s technology, large amounts of raw materials like copper and aluminum will be required to connect the different areas of energy provision, storage, distribution and utilization. according to the International Energy agency’s “global Critical Minerals outlook 2024”, copper demand will exceed the available supply from 2025 on, and thus raw material prices are expected to rise in the future.

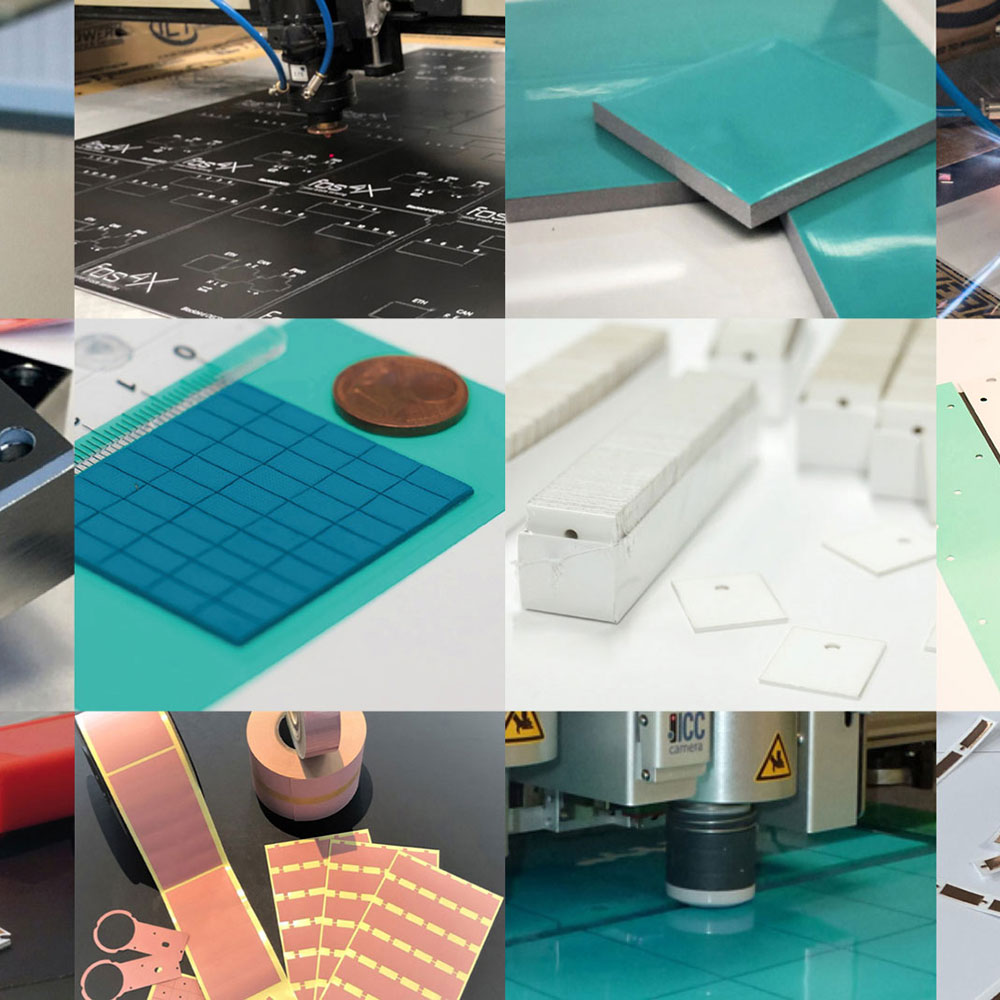

The European Union also identified in the “Study on critical raw materials for the EU 2023” aluminum as further critical raw material with a high economic importance and a high supply risk. Increasing the system voltage can be one solution, as it simultaneously reduces the current, potentially resulting in substantial savings in material, costs and space. However, medium voltage (MV) technology is the key to open the resource-effcient integration of renewables in the energy system. This technology also allows new system concepts for renewable hybrid power plants whose individual components are interconnected via medium voltage.

Motivation for developments towards higher voltage levels

The PV industry is subject to enormous cost pressure. This is one of the reasons why considerable investment has been made in the further development of this technology in recent years. The price per installed kWp has dropped by about 14% per year over time, due to advances in technology and economies of scale in production. Today the costs for the installation and BoS hardware account for over 40% of the total costs. In future, savings in these areas will have a greater impact on the overall price. Medium voltage is a key lever in reducing energy generation costs.

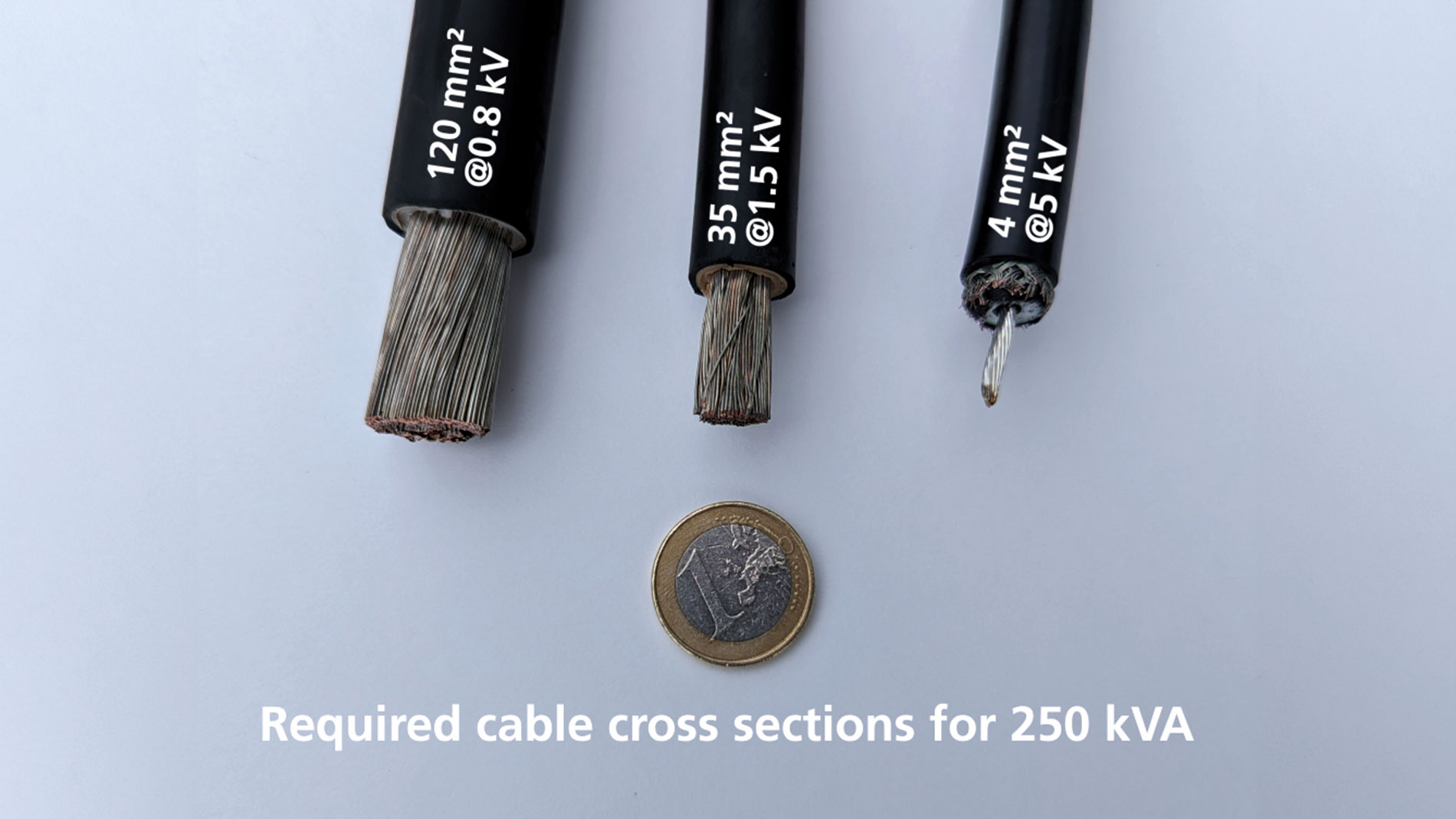

Higher system voltages result in reduced cable currents, leading to savings in many areas. For example, the cable cross-sections can be greatly reduced, thus saving raw materials like copper and aluminum. as shown in Figure 1 doubling the output voltage leads to halving the output current and to a 75% reduction in cable cross-section, considering only the pure current carrying capacity of a single conductor. However, the material costs are not the only savings potential for cables. Installation costs can be saved by smaller cables as well, since they are generally easier to lay and connect.

Another advantage of medium voltage is that higher voltages allow to increase the power of the individual subsystems. Today’s PV power plants mostly use subsystems between 3 and 5 MVA in size, whose output cannot be significantly increased due to the large copper cross-sections necessary for the current in the low voltage range. By switching to medium voltage, a transformer with the same cross-section can transmit a higher power (10 – 12 MVA at 1,500 V). For PV power plants of the same size, the plant with medium voltage technology requires a smaller number of transformers and switchgears. This leads to lower construction measures and installation costs, while freeing up space for additional PV modules at the same time.

State of the art in research and technology

In the early days of silicon carbide (SiC) semiconductor development, there was great euphoria for the technology, and the advantages of wide bandgap devices were demonstrated in a wide variety of components. These included components with blocking voltages up to 25 kV. Even back, higher voltages were being considered in the field of PV and first research projects.

However, the costs of the new semiconductors were still too high, and the technology was still plagued by various teething troubles resulting that components with high blocking voltages were still too far away from being ready for serial production. With the rise of e-mobility and the increasing demand for SiC components < 1.7 kV, all manufacturers focused on optimizing these voltage classes. The further development of higher voltage components came to a standstill. SiC has now fully arrived in e-mobility. More manufacturers are once again focusing on higher voltage classes. 3.3 kV devices are available on the market from various manufacturers and 6.5 kV is well on its way to serial production. In the meantime, various research projects have shown that the construction of highly efficient inverters based on medium voltage SiC devices is technically feasible.

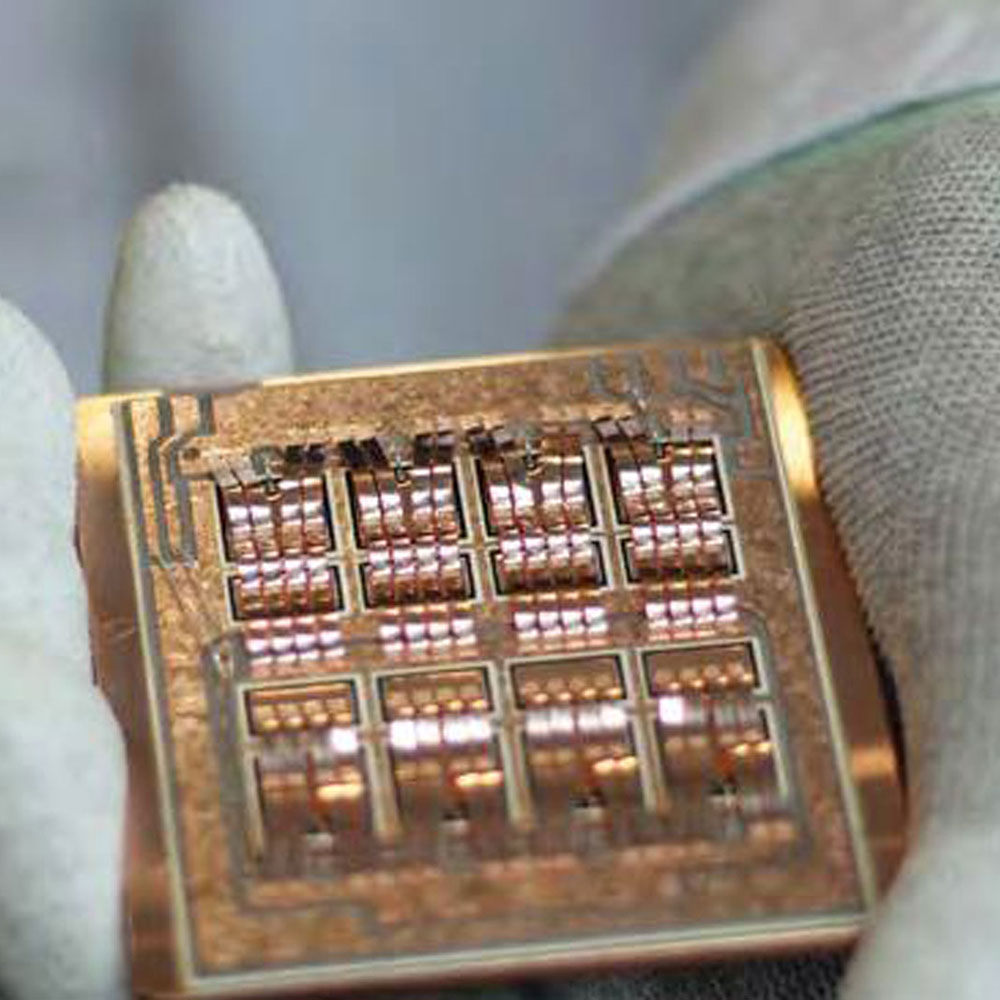

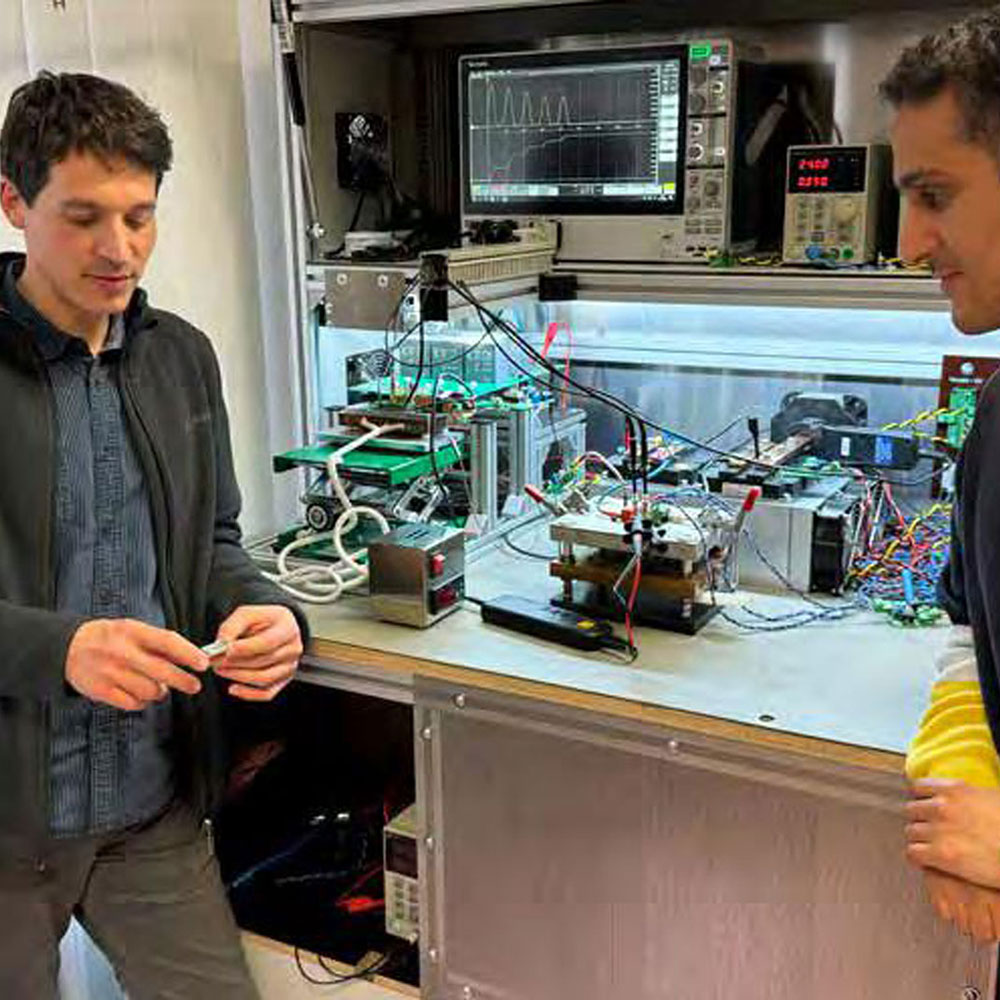

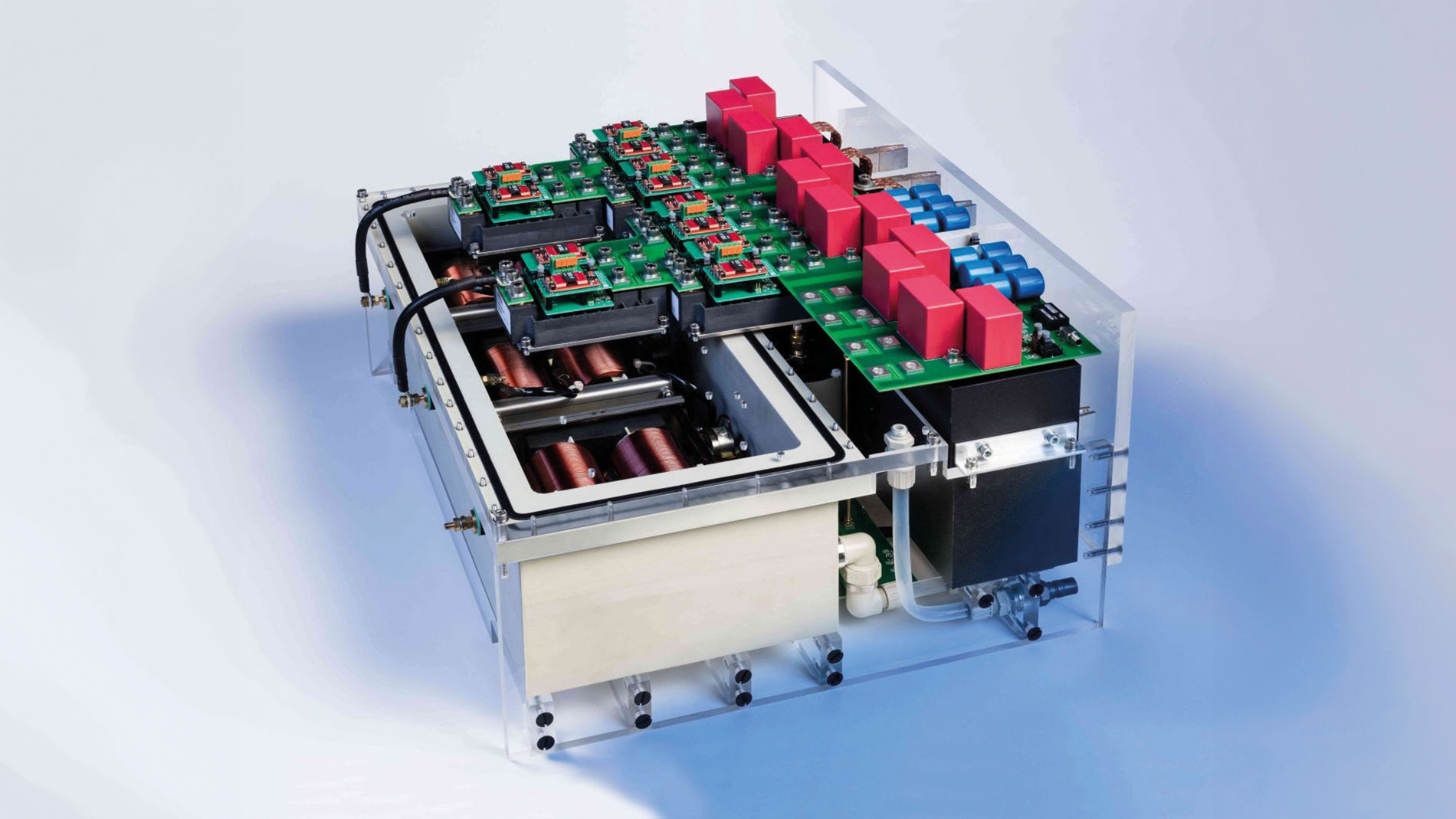

Researchers at Fraunhofer ISE have developed the world’s first medium-voltage PV string inverter and successfully put it into operation on the grid, as shown in Figure 2. It was developed as part of the public funded “MS-leiKra” project. The PV inverter has an output voltage of 1,500 V (AC) with an output power of 250 kVA realized in a two-stage design. The step-up converter with a PV input voltage of 1.7 kV (DC) to 2.4 kV (DC) is based on 3.3 kV SiC devices. The inverter section was constructed using hybrid AnPC (Active neutral Point Clamped) power modules. Four silicon and two SiC semiconductors are used. This topology allows to use the major advantages of SiC.

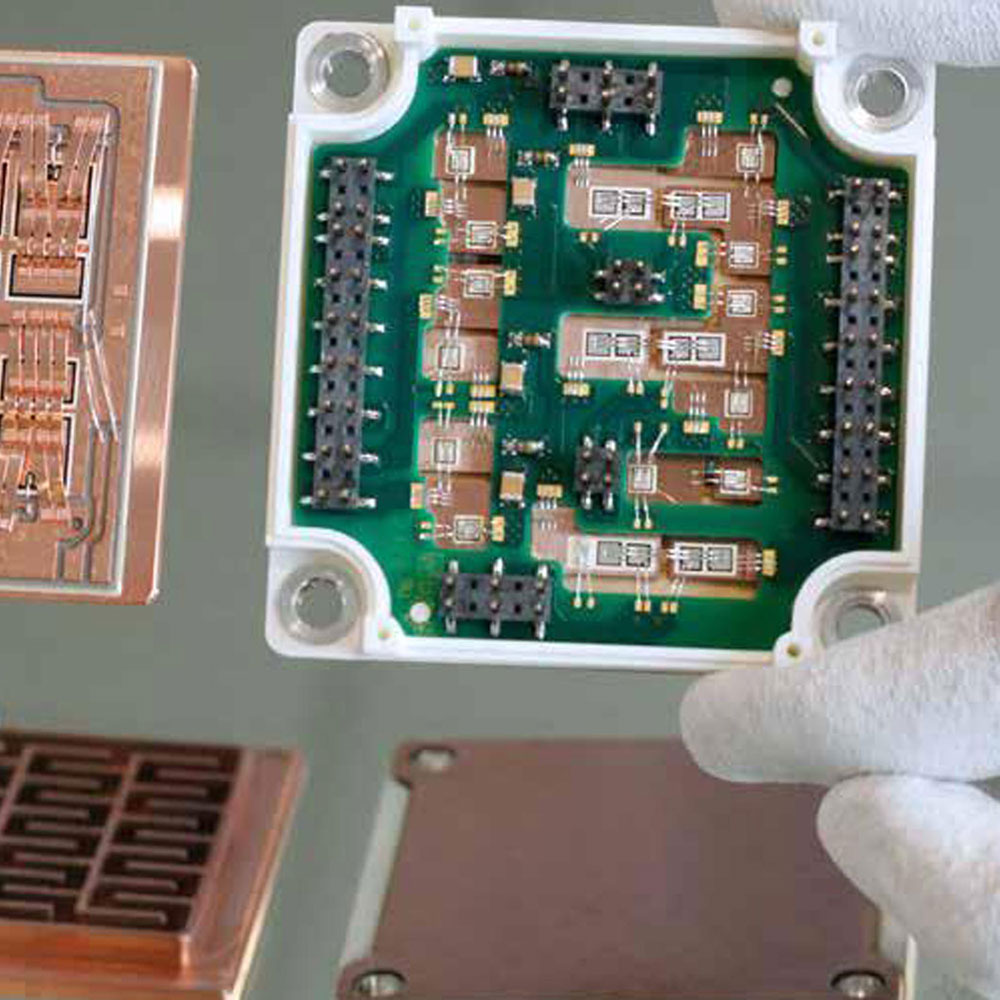

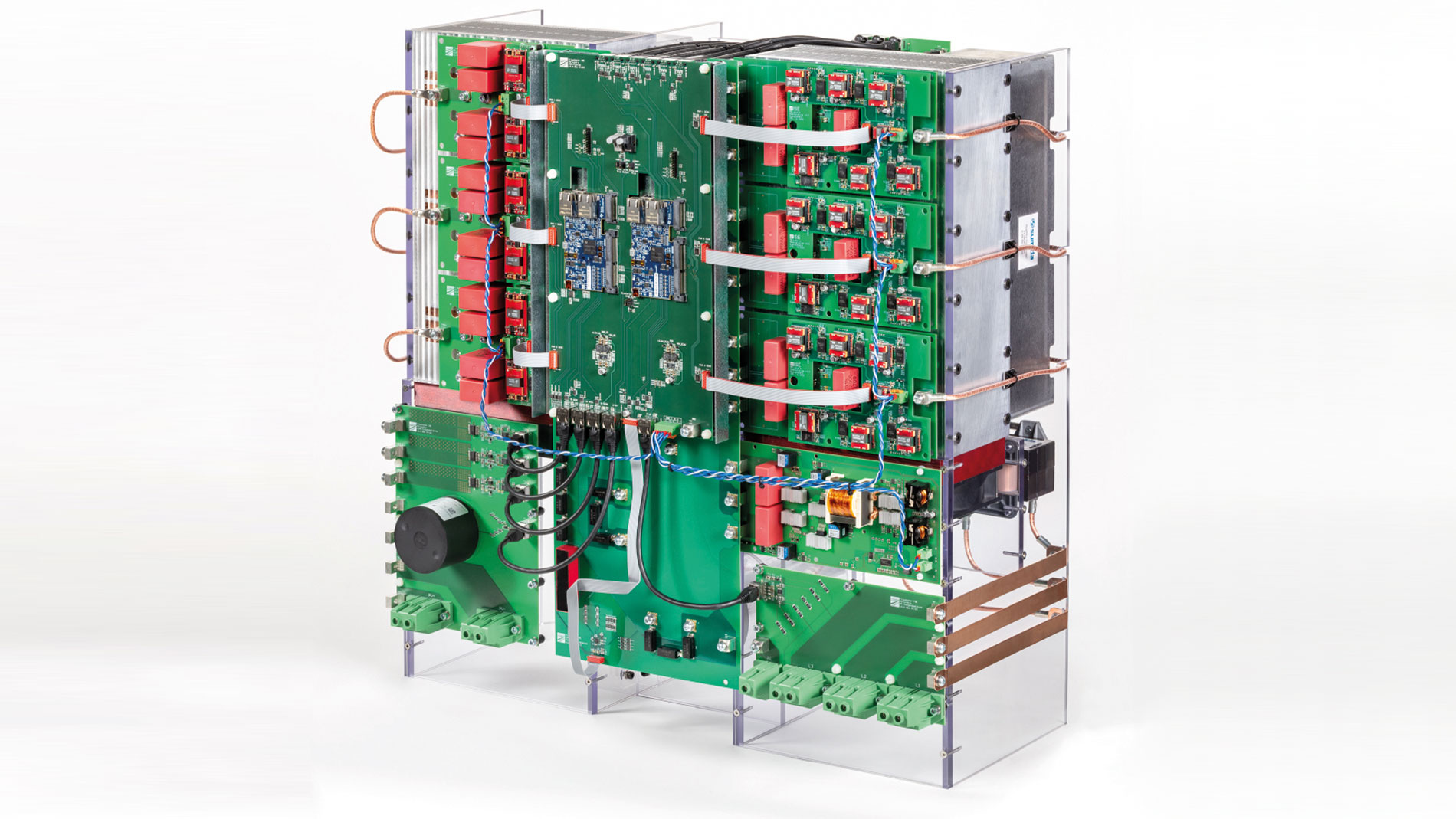

Higher voltages are also possible. A threephase converter with 3 kV (AC)/250 kVA was also developed at Fraunhofer ISE as shown in Figure 3 in the public funded project SiCMS- Bat”. The converter unit can be connected in parallel on the DC and grid side, each with its own lCl filter. It is an AnPC topology used with 3.3 kV SiC devices, using three halfbridge modules per phase. The switching frequency of the transistors is 16 kHz. The PWM-pattern of the AnPC generates a ripple frequency of 32 kHz for the alternating part of the current. This helps to decrease the filter effort. Depending on the design of the inverter, up to 2 MVA can be realized in a control cabinet with a floor space of 80 x 80 cm².

Current situation and the market

The mentioned projects show that the technological course has been set for the transition to medium voltage. At the same time, the technical innovation potential for PV in the low-voltage range is heavily saturated. Technological advances and thus unique selling points are only possible to a very limited extent, making price the main selling point. This poses major challenges for European manufacturers.

The market situation and the rising raw material prices in recent years have increased the pressure to innovate. In the meantime, there have been initial advances in the direction of higher voltages. One example is the “Mengjiawan” project in the Shanxi province of China. Here, a pilot power plant with a DC voltage of 2,000 V was built and put into operation.

The researchers at Fraunhofer ISe are now convinced that it is no longer a question of whether the medium voltage technology will be introduced, but rather who will be the first players in this promising market and thus determine the technology. as already shown, the global demand for installed PV power will be 73 TW by 2050. The share of utility-scale power plants, and thus the area of application for medium voltage, will be between 40 and 60%. This is a great opportunity for european manufacturers to regain technological leadership, at least in utility-scale power plants.

The issue of standardization and overcoming obstacles together

Despite the steadily increasing output power of PV inverters, the increase in system voltage has stagnated since 2018. This is due to the definition of low voltage, which ends at 1,500 V (DC) or 1,000 V (aC). all existing PV standards up to now refer to this limiting value. an increase beyond this value is currently hindered by the existing standards, as they must first be adjusted, or rather extended, to meet the basic standards for medium voltage applications. The good news is, that standardization committees are already looking into the higher voltages and first drafts for PV up to 3 kV are already written.

A European consortium, made up of representatives from all trades involved in large utility-scale PV power plants, has been formed to jointly address and compile the technological and normative requirements necessary for the leap to medium voltage. This powerful consortium that is open to additional participants can tackle the existing hurdles together and achieve optimization throughout the entire power plant.

Applicability to other areas

Utility-scale PV power plants are just the beginning. When individual components are linked together in a resource-efficient way via medium voltage, this allows system approaches for hybrid power plants and the integration of decentralized energy generation to be rethought. It enables more resilient district power supplies, charging infrastructures of electrical vehicles or even operation of industrial grids in heavy industry with reduced dependence on the traditional power grid.

The transition to electric vehicles will be accelerated by the Co2 reduction target and the eU registration change from 2035, according to which only new cars with combustion engines that no longer emit Co2 while driving can be registered. While intensive research is being carried out on vehicles and charging systems, little attention is paid to the connection between the charging station and the public grid to the required provision of power. Currently, cars can be fast charged with up to 850 V (DC)/350 kW. In future, trucks will be able to be charged with up to 1,250 V (DC)/3 ka (DC) in accordance with the MCS standard.

The study “easy Charging at Service areas” by the german national Center for Charging Infrastructure deals with the power requirements of electric charging stations. The study found that fast-charging systems with capacities ranging from 8 MVa to 26 MVa will be required in the future. The requirement for a charging facility for trucks and cars at least every 50 km along germany’s freeways, which covers total of 13,200 kilometers, translates to a total installed charging capacity in the high double-digit gW range. This estimate does not include large electric charging stations in urban areas and charging stations at trucking companies. For large truck stops with up to 150 parking spaces, the charging capacities at night can add up to 5 – 7 MVa, depending on the assumed simultaneity factor.

To relieve the load on the grids, a combination of storage and renewable generation directly on site is a promising solution. Parking lot roofs offer a large PV potential here. However, the connected load must also be distributed on site and routed to the individual charging points. To achieve a high level of efficiency and limit the use of materials, the move to medium voltage offers a sensible approach. As PV, storage and charging technology are DC-based, an MV (DC) bus system would probably be the most efficient solution in the future.

Summary

Contrary to all the hurdles in the past, the signs are currently looking good for the introduction of medium voltage in PV. The technical feasibility has been demonstrated several times. The first steps have already been taken by various manufacturers and the first pilot systems are already in operation. The problem has also been recognized on the standardization side, and the committees are working on the important normative basis for this step towards resource-saving renewable energy generation. There are a lot of applications where higher system voltages enable considerable material, cost and space savings and open new system concepts for hybrid power plants. let’s push forward towards a high-efficient renewables-based energy transition together!