Our origins lie in the planning and project management of wind turbines. After their construction, we also take over the operation and maintenance of the turbines. In the meantime, the focus has shifted to servicing power electronics. Zopf is known worldwide for offering high-quality power modules, far beyond the wind energy sector. Zopf’s goal has remained unchanged for over 30 years. We do our part to generate energy sustainably and fairly and to help shape the defossilization of the industry. We want to provide energy responsibly.

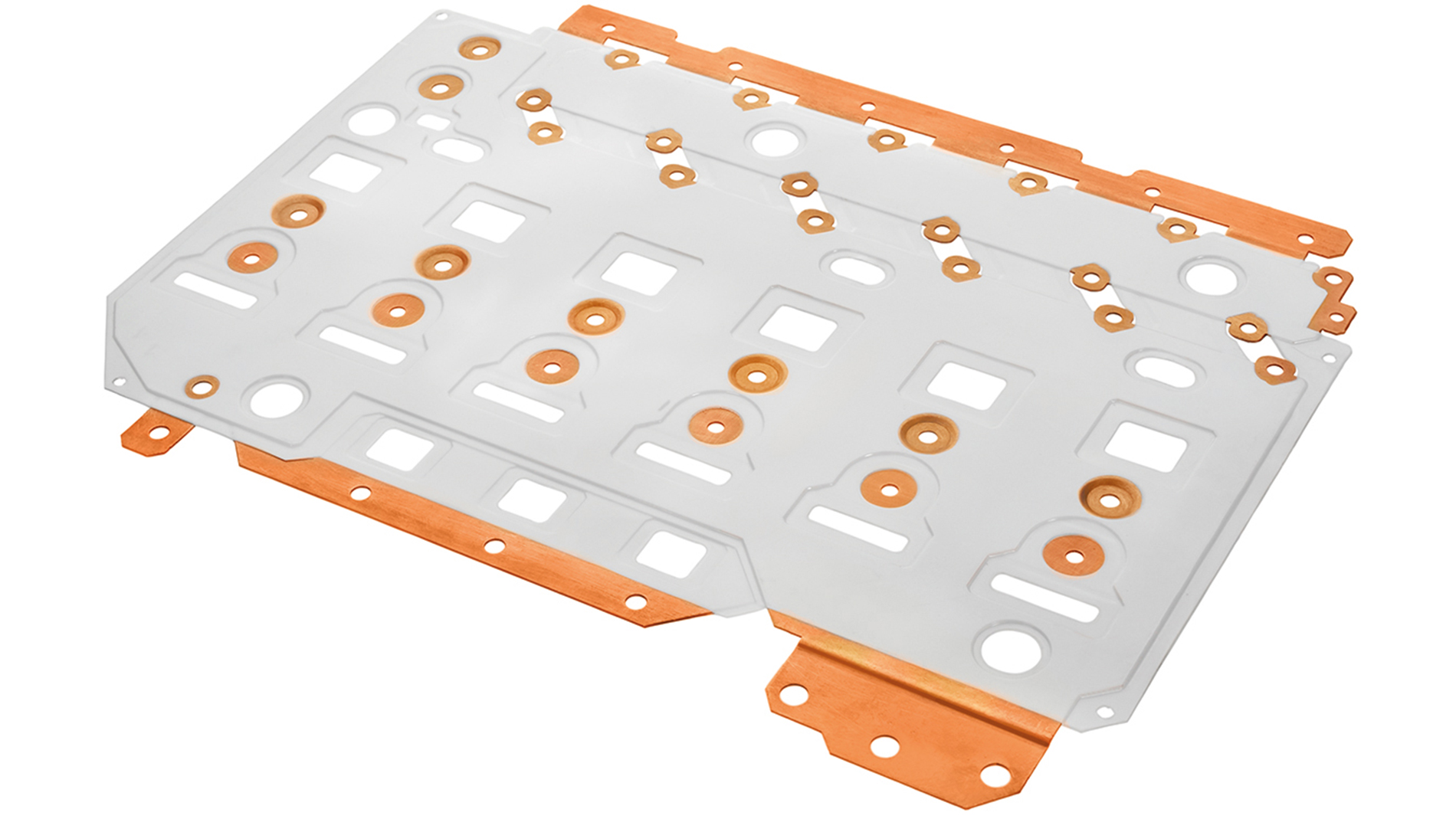

Since January 2025, a new plant has been added in Wickede (Ruhr) in North Rhine-Westphalia, which focuses in particular on the production of busbars. Zopf develops and manufactures laminated multilayer busbars there. We specialize in complex, customer-specific solutions in which safe power connections are required in the tightest of spaces with secure wiring.

Busbars can be manufactured up to a size of 1 m x 2 m (1000 mm x 2000 mm) using a laminating press. Copper is purchased in Europe and 100 percent of the production takes place in Germany. This guarantees short delivery times. Our in-house toolmaking enables a fast and close exchange with the customer’s engineering team. Smaller quantities of between 100 and 500 units are also possible.

As part of our in-house production, we undertake individual punching, bending, and assembly work. The production of precisely fitting insulation foils using plotter cutting is just as possible as the assembly, pressing, and soldering of electrical components on the busbar. The quality standards set here are verified and documented as part of various test procedures.

At its Leipzig site, Zopf also develops and manufactures complete power components for customers in the aftermarket or for OEM converters/inverters.

Advertisement