Vision technologies is an automotive and industrial core production company. We have a quality that highly competitive in market for both lamination and wounding core. Vision technologies can supply the customers requirements using high quality raw materials from overseas.

Manufacturer of magnetic material part for automobile, industrial, home, medical and shielding.

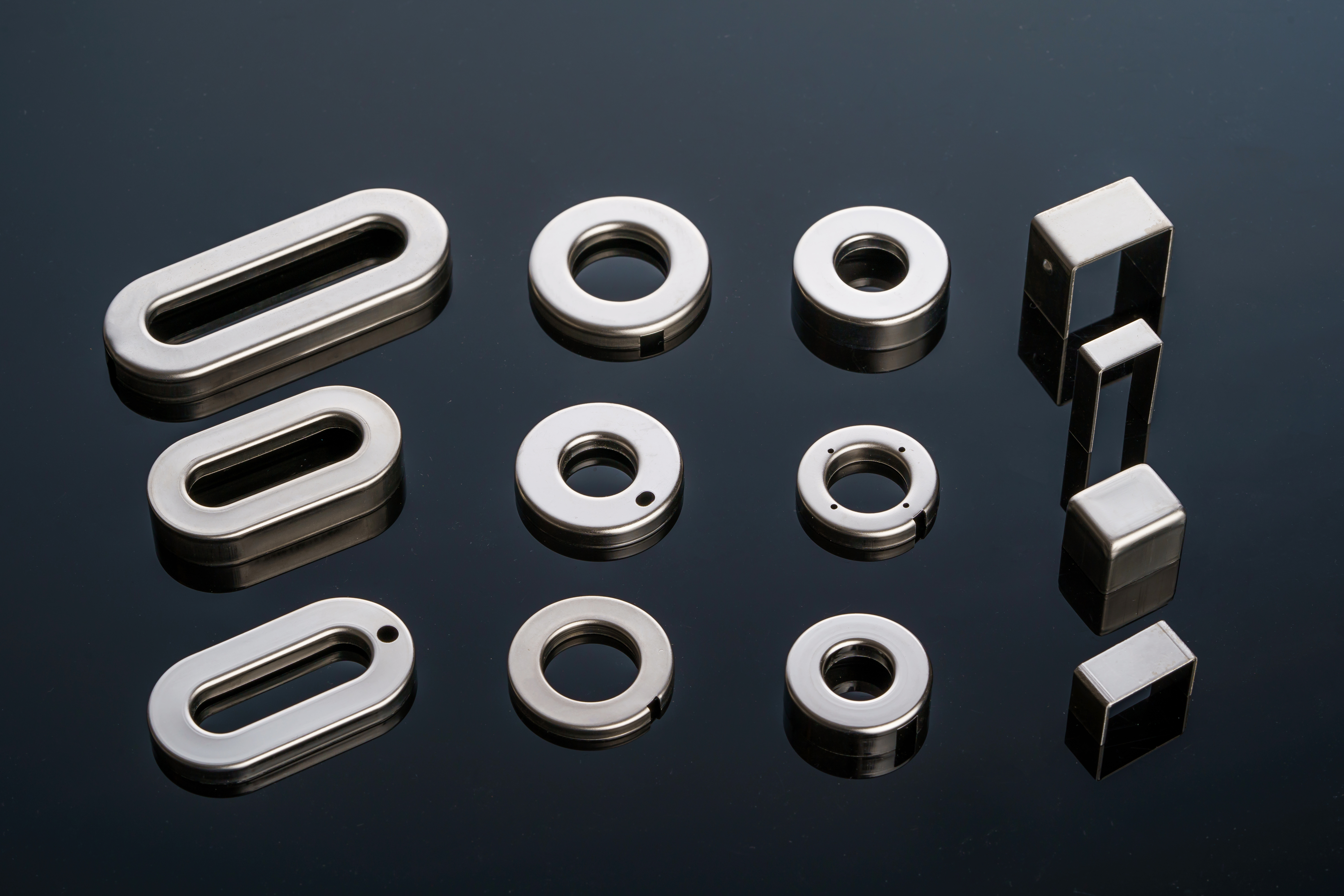

Manufacturing cores of various magnetic materials

We manufacture cores of various magnetic materials such as permalloy, silicon steel plate, nanocrystal, amorphous, and cobalt steel plate.

Sample production method with low initial investment allows customers to easily perform various analyses and initial access.

We have competitive overseas factories in the Philippines and China.

The Philippine factory in particular is an ideal alternative to the US-China trade conflict.

We have been supplying large quantities to electric vehicle charging system parts companies and current sensor companies around the world since early 2019, and have established sufficient equipment and quality systems to maintain stable quality and price competitiveness.

We can offer competitive unit prices compared to other companies.

We have equipment specialized in mass production and have higher production capacity than other companies, so we can provide them at low prices and short delivery times.

We use cores used for high-precision measurements, and can produce low-cost, high-quality products with low labor costs at overseas factories.

Long-term experience in overseas exports

We export a lot to the US and Europe, with Japanese companies accounting for a large portion of our sales.

We can provide solutions that can be applied to electric vehicles through our extensive experience in home appliances and industrial applications.

We produce cores applied to precision motors for aviation, space, medical, etc., rather than ordinary motor cores. It is possible to stack thinner steel sheet raw materials to a higher height than in normal motors.

In addition to silicon steel sheets, it is possible to produce cobalt motor cores for UAM that achieve high torque.

We have participated in early development and have a more stable production line than other companies for electric vehicle chargers and DC-DC converter shielding cases.

Various processing techniques allow us to produce cores according to the performance desired by our customers (pressing, winding, cutting)

We produce rotor and stator core. Now it used for industrial component, but it is very precise than others. We can stamp very thin thickness like 0.2t, so that can satisfy customer that want high quality motor.

Hall sensore core is component of inverter, converter in BMS. In EV market, customer want faster charging speed, so that it needs more powerful measuring current sensor. Vision use various raw material and production way to satisfy customer new design.