Search and find – our supplier directory provides a comprehensive overview of industry players, featuring detailed profiles of the PCIM Expo exhibitors 2025 as well as the latest solutions and products in power electronics.

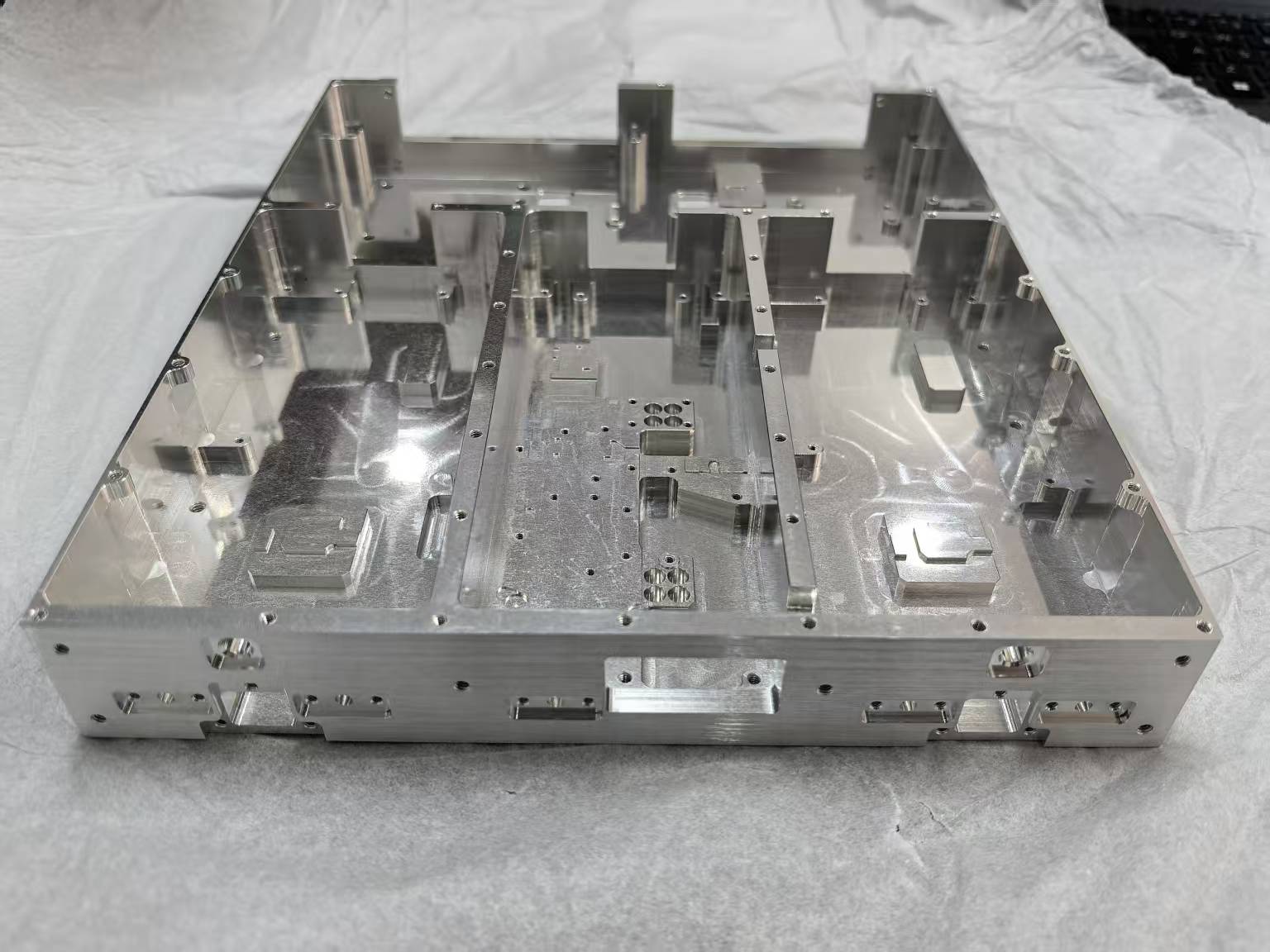

Sheet metal parts

Description

Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses cutting, bending, forming, riveting and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, and copper. It can be as thin as a few thousandths of an inch or as thick as several millimeters.

Sheet metal parts are used in cars, medical, airplanes, industry and other appliances. The manufacturing process starts with selecting metal and cutting it into the desired size and shape. The metal is then formed into its final product through various techniques, such as punching rolling, extruding, and bending. The end product can vary from simple flat panels to complex three-dimensional structures.

Goldconn offers both hard stamping and laser cutting&NCT punching for sheet metal parts. The Hard stamping processes utilize punch presses with custom-made tooling and dies to produce a shape, pattern, or other characteristic a part requires. In general, the stamping process can provide tighter tolerances than sheet metal fabrication. It is a fast and cost-effective way to produce metal parts in large quantities. And the laser cutting&NCT punching is the more economical way to produce parts in lower quantities, as the tooling associated with stamping can be costly. also provides greater design flexibility than stamping, as there is no tooling to change should your part design require alteration. so laser cutting&NCT punching is popular for customers to do small quantity or trial run to get qualification prior to mass production.

Address

Goldconn Technologies Company Limited

Guangdong Dongguan LiaoBu Town

Taihe Road, Daxiandi Industrial Park No.5 /

523425

China

Telephone+86 769 8352 1488

Discover more from us