Search and find – our supplier directory provides a comprehensive overview of industry players, featuring detailed profiles of the PCIM Expo exhibitors 2025 as well as the latest solutions and products in power electronics.

Bizon Press-Fit-Technology

Description

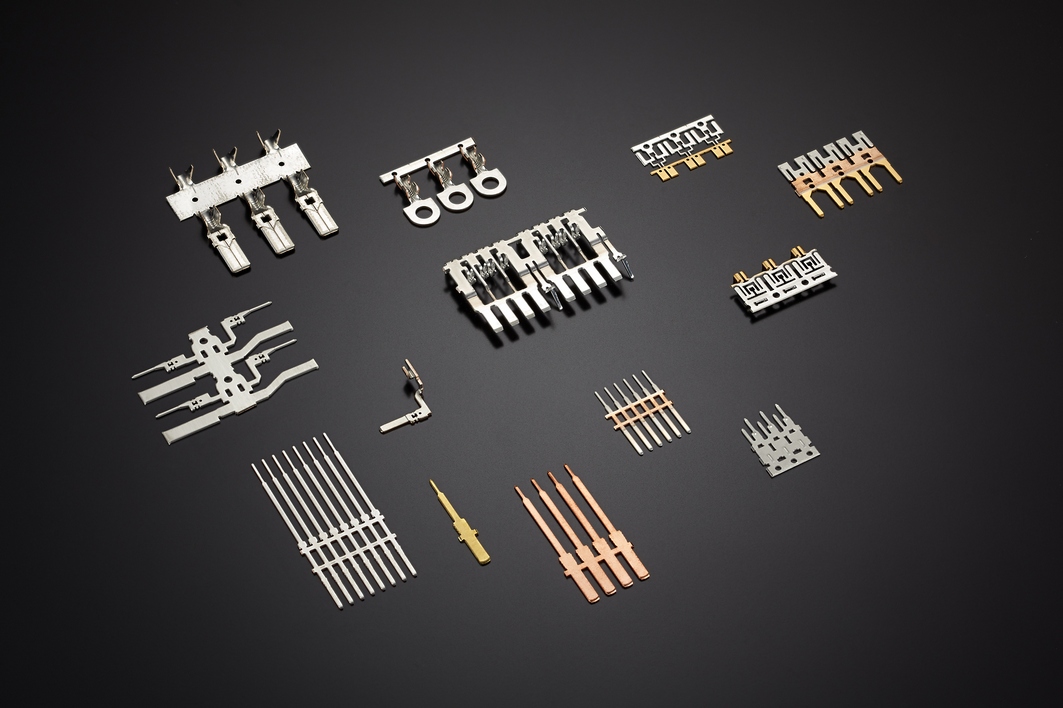

A press-fit zone with particular flexibility

We can give you broad-ranging design flexibility in terms of material selection, material thickness, material strength and adaptability to your specific needs and technical requirements. Made to measure exactly to the customer's needs. Providing BIZON® press-fit technology, ZETKA offers an innovative solderless contacting system for all requirements in the automotive supply industry, electrical engineering, power electronics and any other application where secure contact connection to a printed circuit board or metal plate defines the quality of the final product.

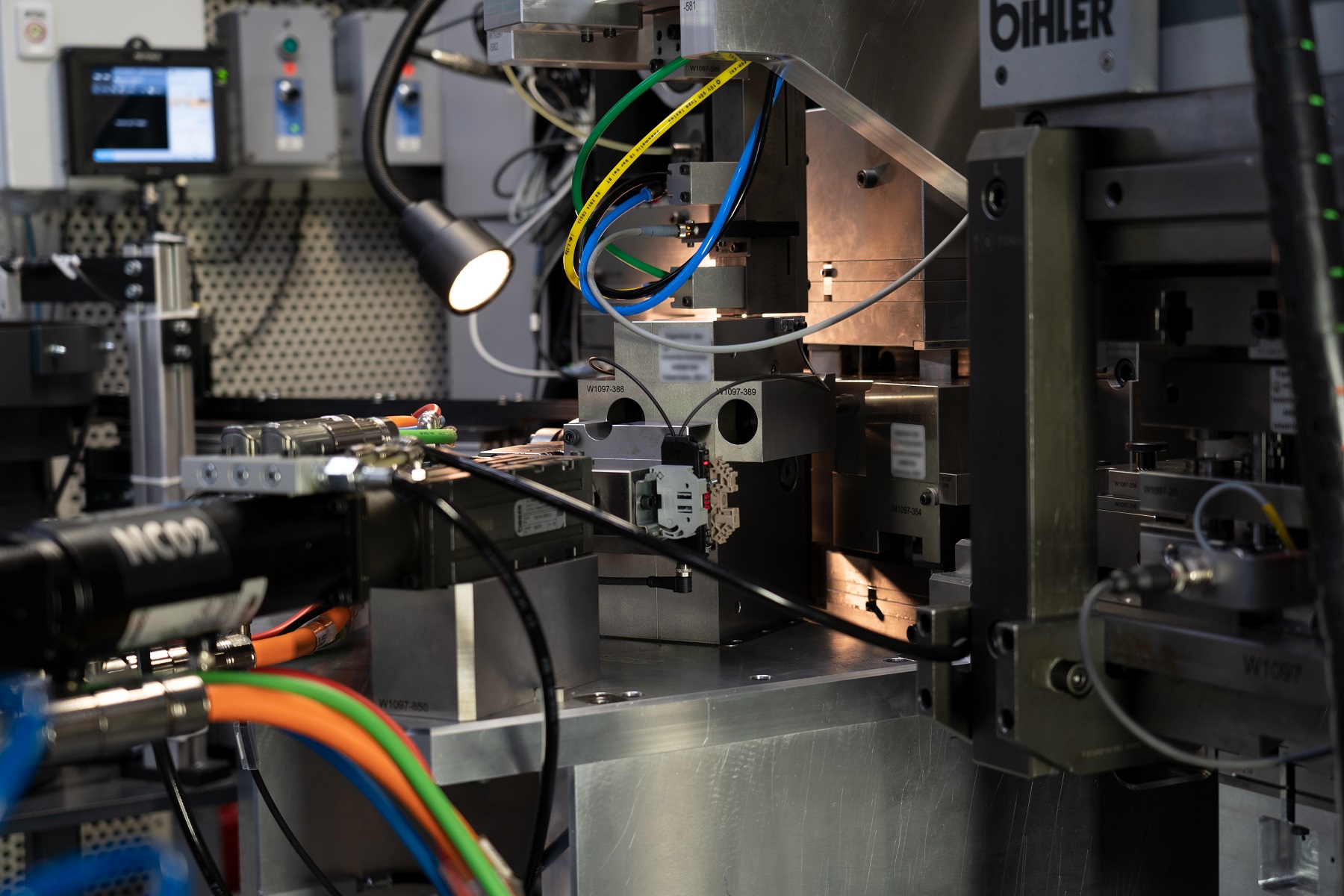

Solder-free, robust and secure

This press-fit technology is a solder-free, robust, secure electrical connection technology in which preferably elastic, formable pins are connected into metallised (copper-plated) printed circuit board holes with defined dimensions at a defined speed using a press-fit facility. This produces a permanent gas-tight mechanical and electrically low-resistance connection (cold welding) at the contact surfaces between the press-fit pin and the hole's metallic inner wall. The unique spring properties of the BIZON® press-fit contact prevent any damage to the printed circuit board if the press-fit process is carried out correctly, thereby preventing delamination (whitening) and tearing of the inner layers.

Press-fit technology for high-current applications with optimised maximum contact surface

The key aspect and major benefit of BIZON® press-fit technology lies in providing the greatest possible square cross-section with accurate self-centring in the PCB hole. The conductor cross-section this achieves is approx. 72% of the hole cross-section, permitting a high electrical strength per contact. With its four defined contact areas, each BIZON® contact provides maximum contact surfaces and, as such, outstanding and secure contact properties. This provides the capability of safely handling several hundred amperes with standard 75 µm printed circuit boards (70 A per contact, hole 2.0).

This is a key cost advantage for any high-current application. Depending on the application, you can avoid unnecessary cost and time-intensive surface finishes in the press-fit zone by using bare BIZON® contacts. This prevents the formation of whiskers and tin chips which can lead to failure of the entire assembly down the line. The contact can be produced in any size and sheet thickness of any material you choose. Exact harmonisation with your particular application can avoid the need for expensive special materials by using standard materials. Let us show you the options and limits.

Discover more from us