Search and find – our supplier directory provides a comprehensive overview of industry players, featuring detailed profiles of the PCIM Expo exhibitors 2025 as well as the latest solutions and products in power electronics.

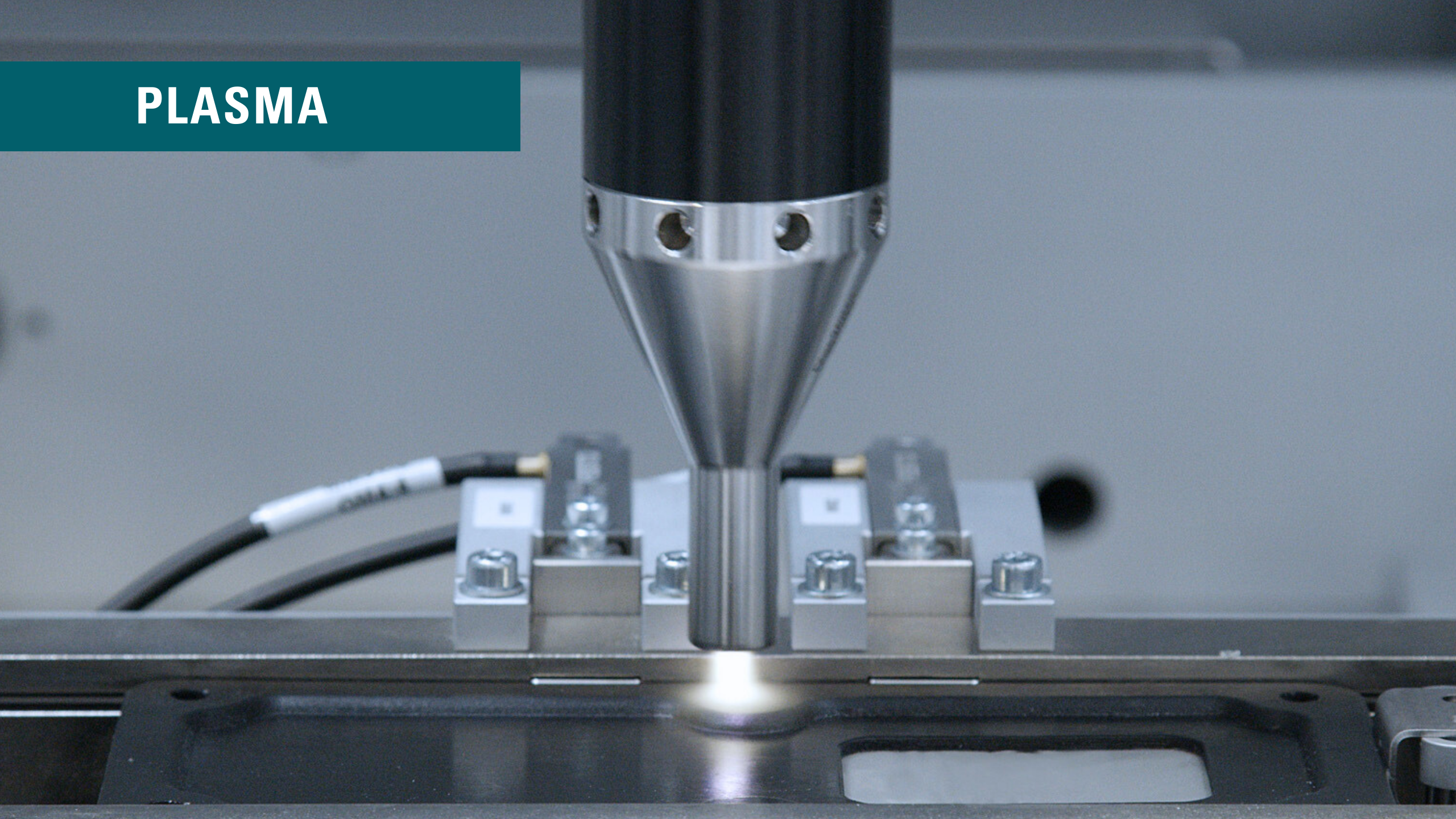

Plasma technology

Description

Optimal Surface Preparation for Adhesive and Sealing Processes

Plasma technology is the ideal solution for cleaning and activating surfaces prior to adhesive bonding and sealing processes, ensuring reliable and durable connections for advanced electronic and semiconductor components.

Long-Lasting Adhesion

Adhesive bonding is becoming increasingly important in modern industrial manufacturing. Whether it’s multi-material combinations (so-called sandwich structures), complex geometries, innovative materials, or reduced adhesive quantities – these challenges are met with plasma technology. For decades, plasma has been utilized to enhance adhesion by cleaning and activating surfaces.

Plasma removes contaminants from surfaces while generating functional groups. This has dual benefits: it improves the wettability of surfaces, enabling optimal distribution of applied materials, and it enhances bonding by forming strong chemical interactions with adhesives and potting compounds. The result is improved adhesion, long-term stability, and increased strength and sealing performance.

Meeting the Challenges of Modern Bonding

In product development and manufacturing, adhesive bonding is increasingly in focus due to rising demands and the growing use of mixed materials. A perfectly prepared, adhesive-ready surface is essential for meeting these requirements.

Discover how plasma technology can optimize your processes and ensure reliable results in demanding semiconductor applications.

Get more information at our booth 4/123 or online: https://www.bdtronic.com/en-en/plasma-technology/

Discover more from us