Search and find – our supplier directory provides a comprehensive overview of industry players, featuring detailed profiles of the PCIM Expo exhibitors 2025 as well as the latest solutions and products in power electronics.

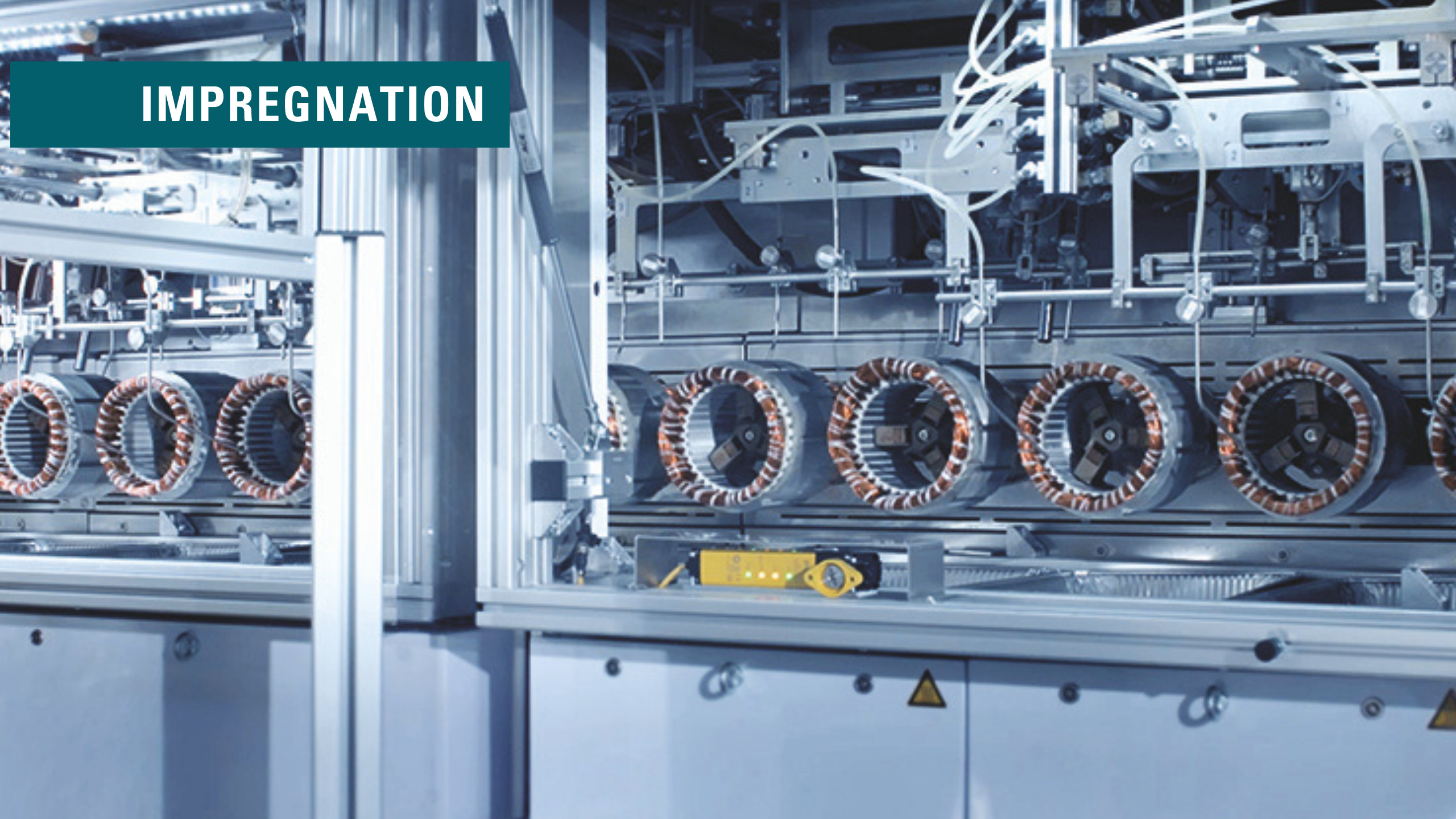

Impregnation of electric motors

Description

Customized Impregnation Technology for Electric Motors with Highest Series Production Quality

Impregnation technology is essential for manufacturing electric drives, whether for hybrid vehicles or fully electric cars and trucks. By filling and sealing the gaps between copper wires or hairpins, it improves electrical insulation, prevents disturbances caused by vibrations, and enhances thermal conductivity. A clean, controlled process ensures that impregnation contributes not only to motor performance but also to a better environmental footprint.

Process Quality Through Precise Production Systems

In the impregnation of stators and rotors, the correct amount of resin and optimal curing and gelation conditions are critical. This requires perfect alignment between resin, machines, and process parameters. In our technology center, we develop optimal procedures for series production using extensive testing and analysis capabilities. Our fully automated production lines deliver high-quality results with short cycle times, low total cost of ownership (TCO), and a clean impregnation process.

Sophisticated Thermal Management for Tailored Processes

Effective thermal management is crucial for even heat distribution during rotor/stator impregnation or the powder coating of hairpin stators. It ensures uniform resin distribution, excellent insulation properties, and flawless coatings. This improves durability and protects against environmental influences, even for complex designs.

High-Performance Motors Through Superior Resin Fill Rates

Fill rates exceeding 99% are essential to minimize the risk of partial discharges. Our trickle impregnation process achieves results comparable to traditional dip impregnation while being significantly cleaner, thanks to precise process control.

Leverage our extensive experience to achieve maximum performance and durability for your electric motors in hybrid and electric vehicles.

For more information on our impregnation technology, visit our website: https://www.bdtronic.com/en-en/impregnation-technology/

Discover more from us