Subtle changes with big impacts

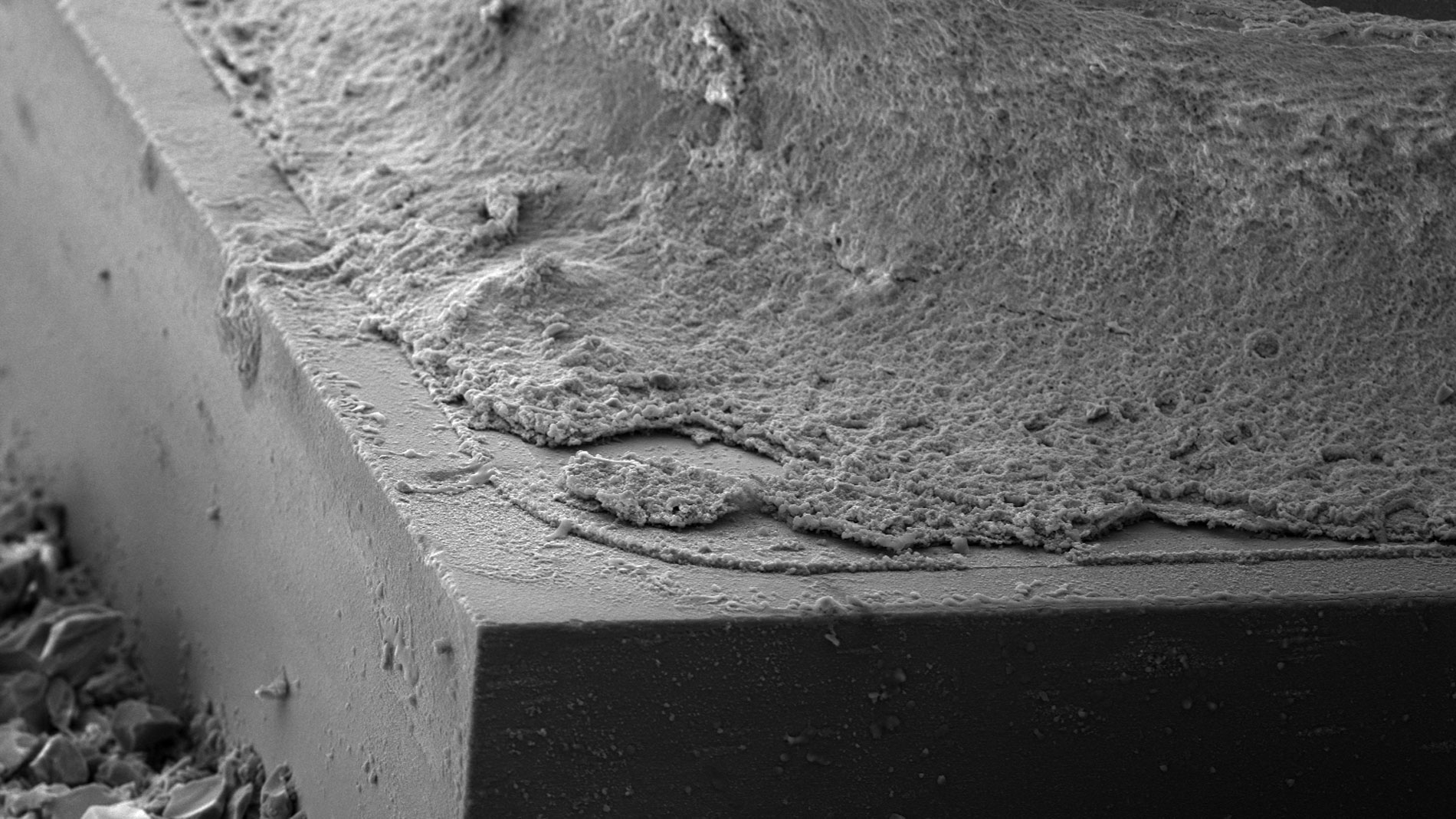

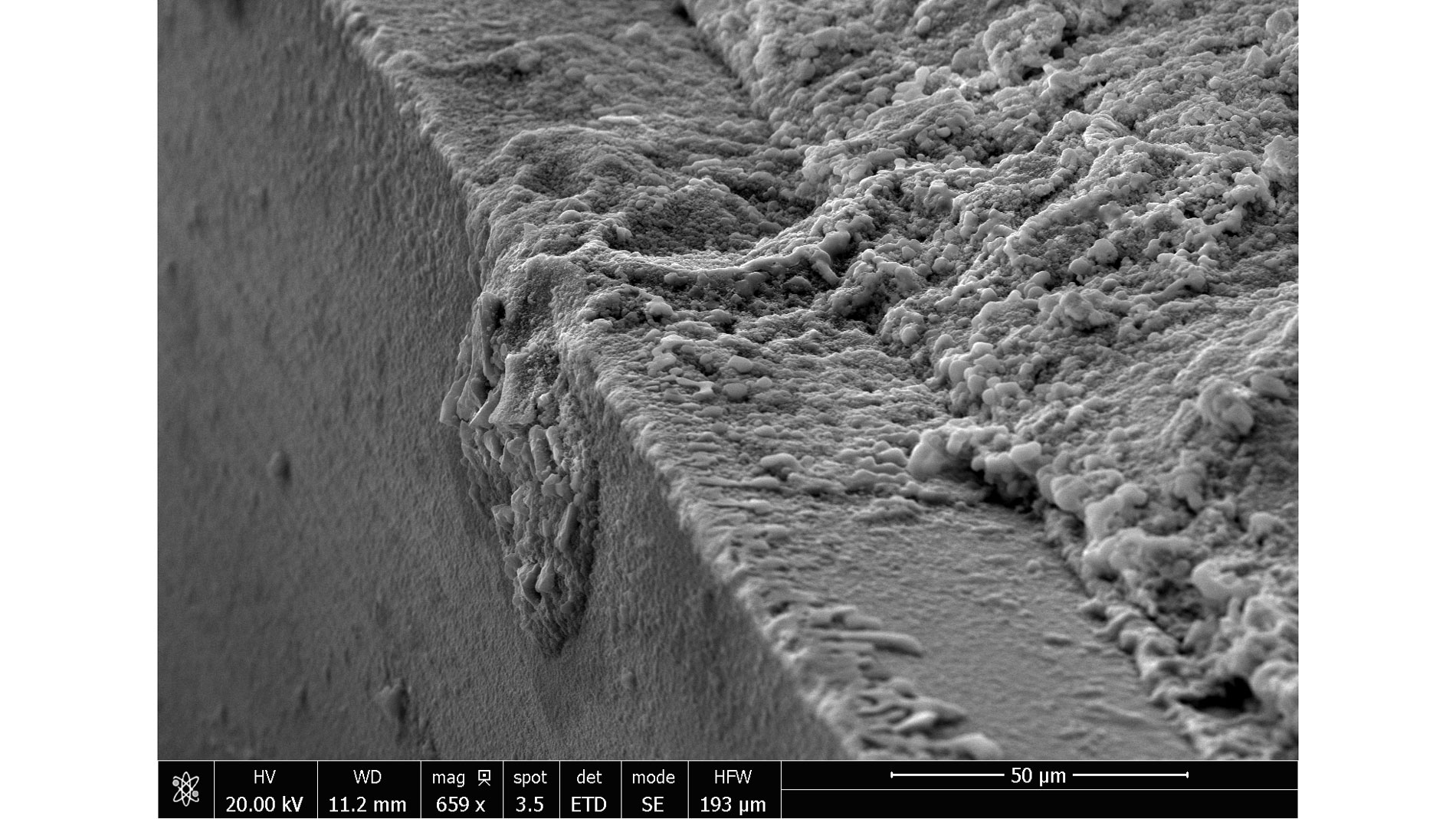

Corrosion of electronics can affect operation by different means. Perhaps the most important failure mode is caused by the formation of water-films on electronic surfaces exposed to hu-midity. This can lead to unwanted leak currents, or electrochemical migration (ECM). Another common problem is the formation of conductive anodic filaments (CAF) within the laminates of printed circuit boards. These can compromise functional performance, or cause failures. But particularly in high voltage applications, the resulting potential for short circuits can ultimately result in the outbreak of fire.

As corrosion is a robustness issue, failure often happens suddenly when exposure conditions are conducive. This is why it is important to understand the mechanisms and factors in-volved thoroughly, and to know how to inter-pret the impact they can have, to try to remove factors that cause interaction with humidity, for example. The Centre for sion (CELCORR) at the Technical University of Denmark has more than 16 years of expertise, across industries and around the world, in solving corrosion challenges in electronic systems.

Identifying vulnerabilities for power electronics

CELCORR has long worked on joint industry research programs as part of an industrial consortium, and it is out of this work that it identified a specific need to extend its capabilities in developing preventive solutions for power electronics applications. The resulting Centre for Climate Robust Electronic Design (CRED) funded by the Poul Due Jensens Foundation, Denmark, is helping CELCORR to develop practical and experimental expertise for environmental effects in high voltage/ power electronics and different application situations. These are unique capabilities, that combine materials, corrosion, and electronics knowledge to understand root cause and using Electronic Corro- that understanding to boost robustness. The goal is to have a body of know-how that can be widely used for designing better devices and systems, from EVs to wind turbines or other applications.

Unlike other research groups with power electronics background, the centre approaches issues from a unique corrosion and materials perspective, looking at the interactions of ma-terials with conditions, that is, the aspects of surfaces, interfaces, process related factors, and so on. This makes it possible to identify the root causes of vulnerabilities: information that can be used to replace, modify, or adapt designs to attain greater robustness and ex-tended product lifetimes.