Grid code requirements for consumption

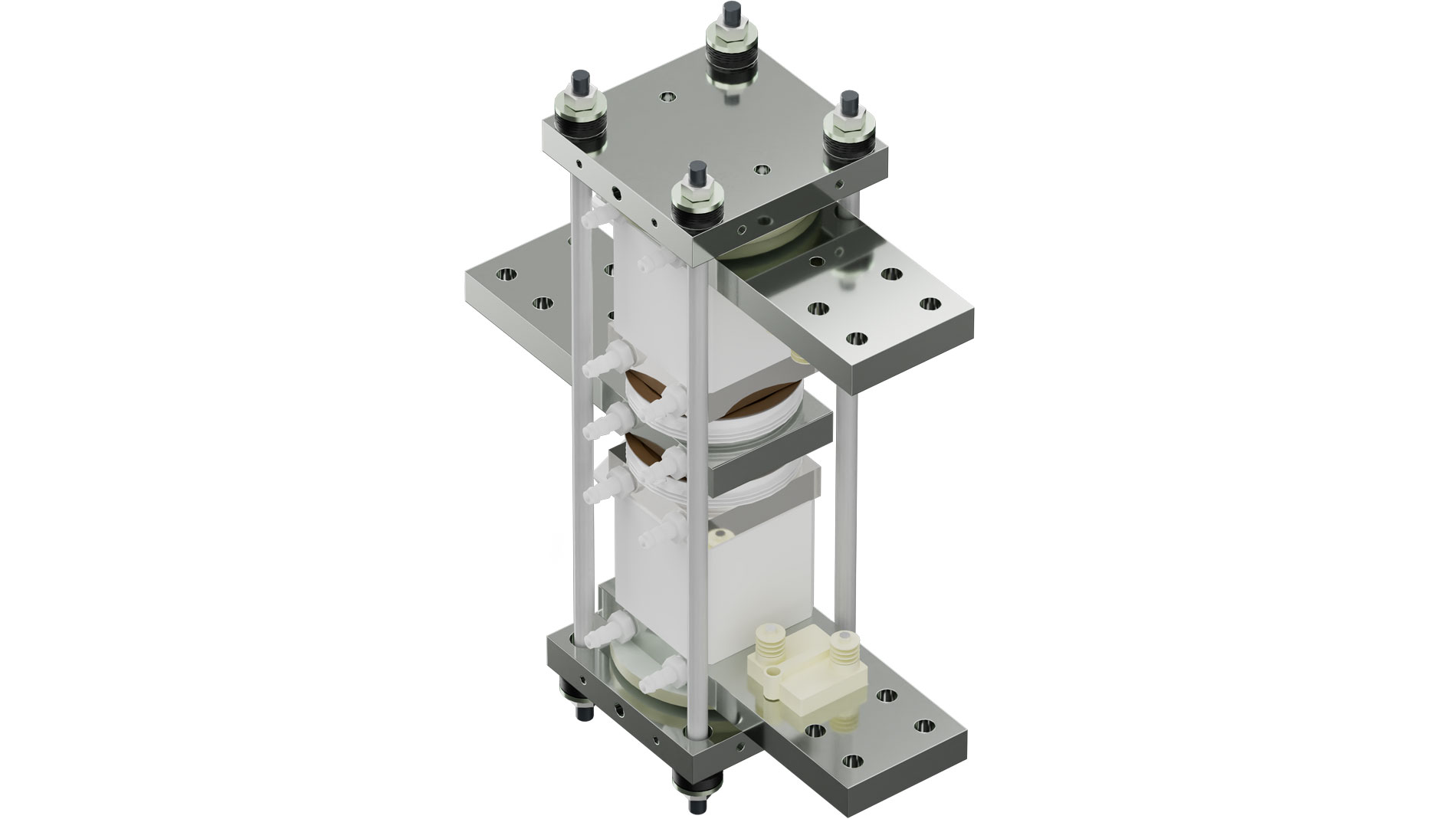

Integrating electrolysers into the grid is part of the overall challenge for power electronics to provide distribution system operators with the control they need of the modern energy landscape. The attention has been on updating the grid code to ensure power quality and grid stability, and to accelerate the integration of renewables. Much of this is to support the grid under different fault scenarios, such as voltage or frequency changes, short circuits, and so on. Not as much work has been done specifically on the consumption side. This is where electrolysers fit into the picture.

As potential consumers of hundreds of meg-awatts, electrolysers do have a role to play in supporting the stability of the grid. This is usually by meeting requirements for total har-monic distortion (typically <5%) and power factor (typically >0.95).

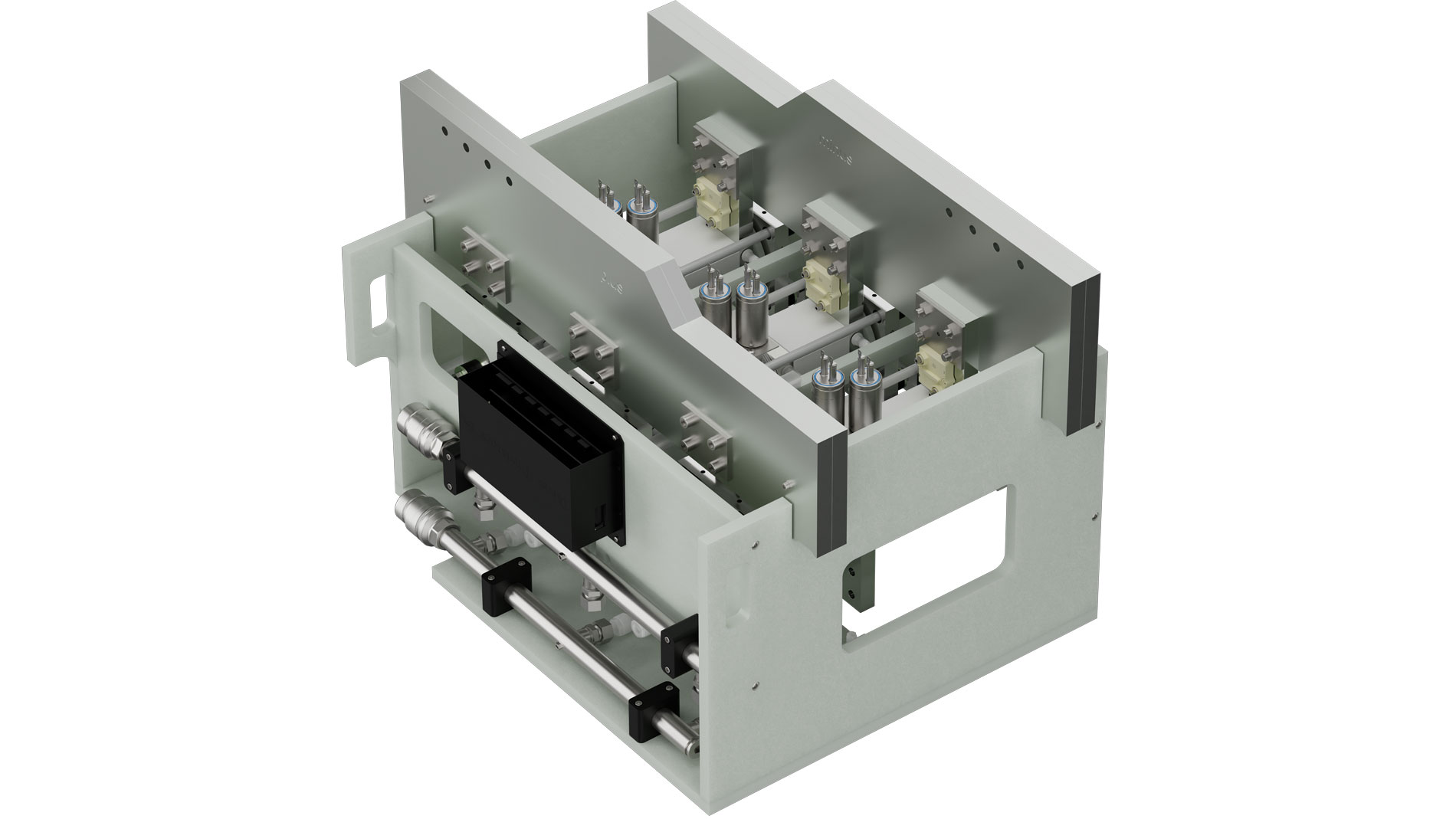

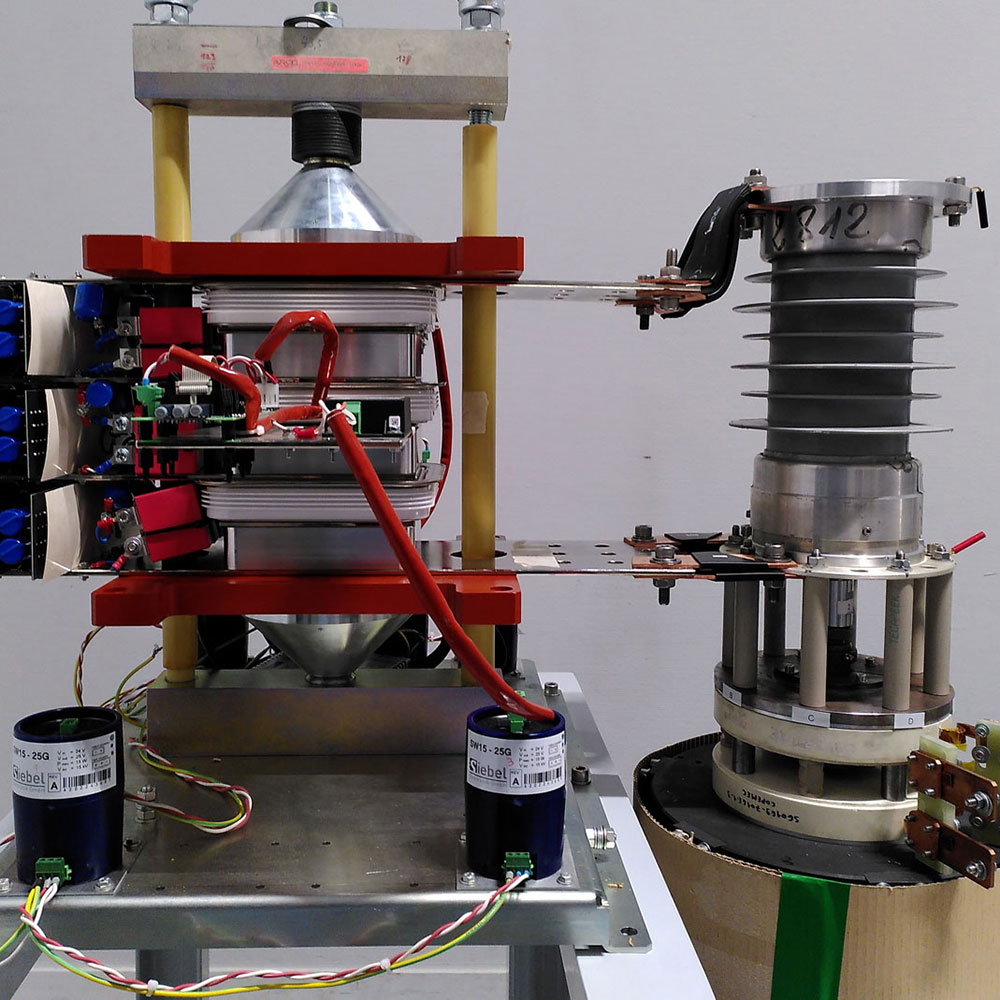

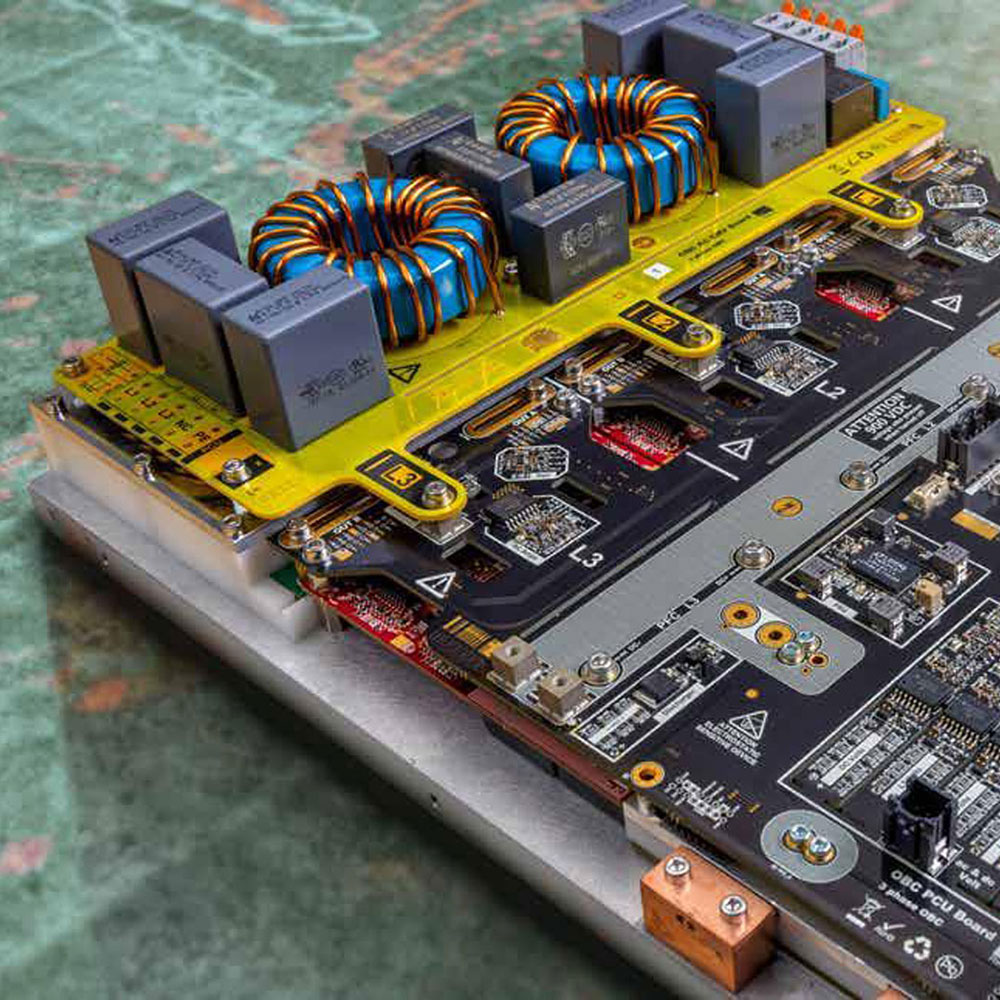

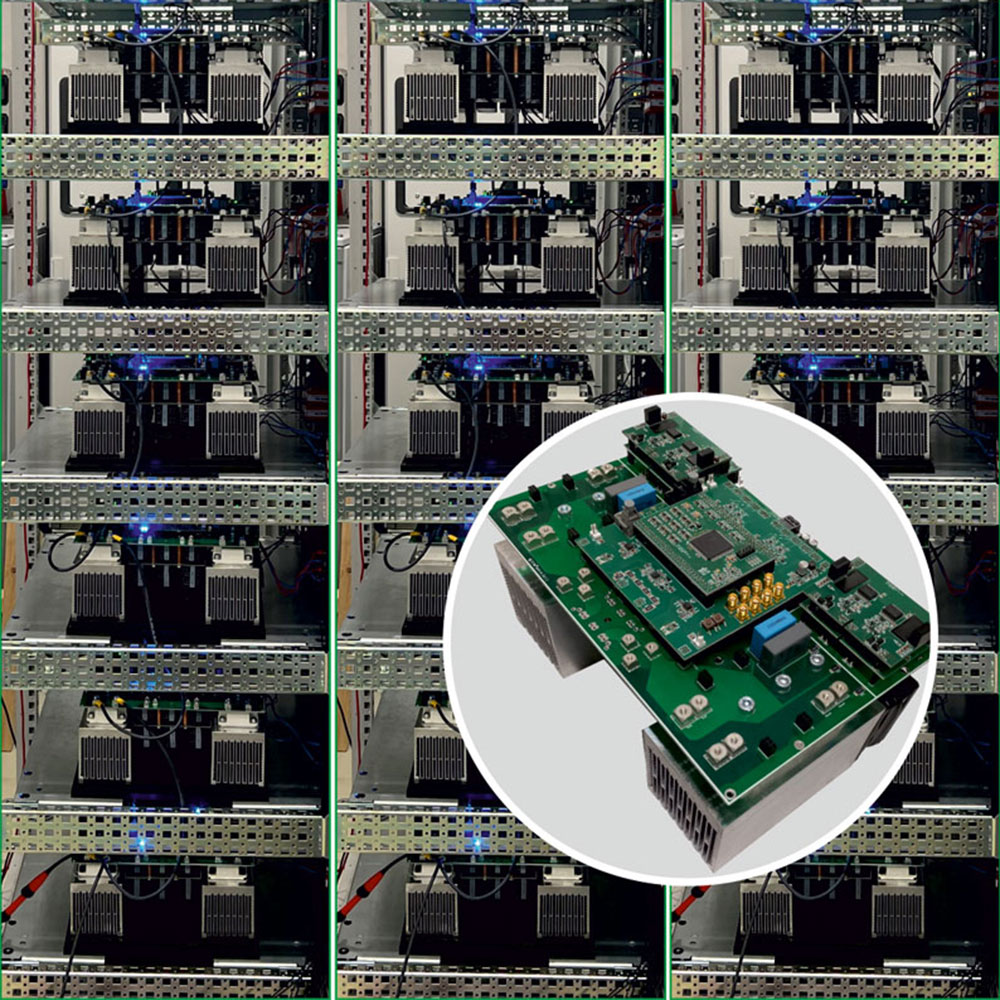

Power electronics topologies for electrolysis

Familiar power electronics technologies – as are often developed for generation systems – tend to have more capabilities than an electro-lyser needs. These solutions are over-specified for “just” keeping total harmonic distortion and power factors in check. While they might provide extra capabilities that are nice to have, this can mean higher capital expenditures.

The choice of the right topology is influenced by a number of other considerations. These include technical issues at the point of common coupling, such as the robustness of the grid (affecting the impedance needed), and whether the electrolyser is at the start or end of the generation line. Then there are factors that influence operational costs, such as levels of efficiency and reliability, and ease of maintenance, as well as any size needs for the specific implementation. Taking such factors into account can optimise operational expenditures, to minimise the total cost over the lifetime of the device.

This involves carefully considering the different technologies available, such as IGBT-based, thyristor- or diode-based solutions, along with passive or active compensation to manage power factor and harmonic requirements. Each option presents its own unique considerations, and the decision should be based on a thor-ough evaluation of technical and operational factors to optimize overall costs.