Prof. Dr. Leo Lorenz, President, ECPE European Center for Power Electronics e.V., General Conference Director PCIM Conference

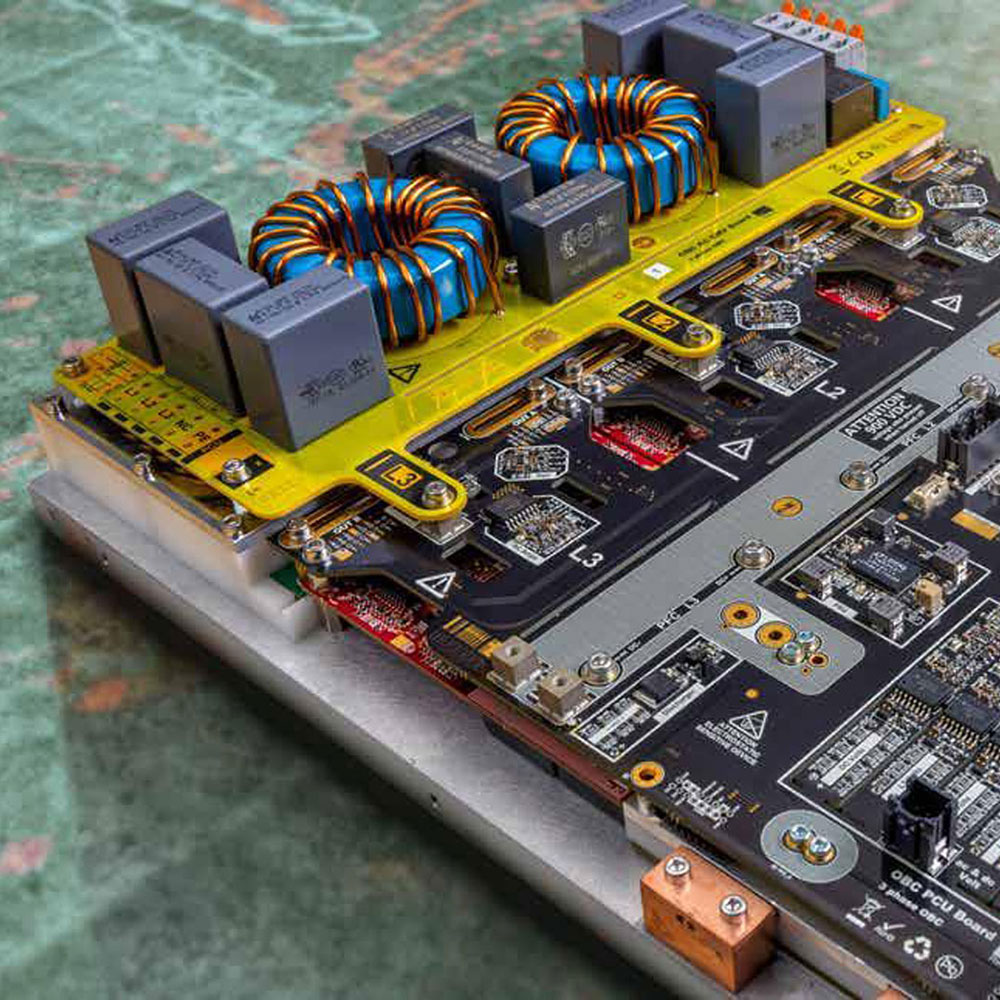

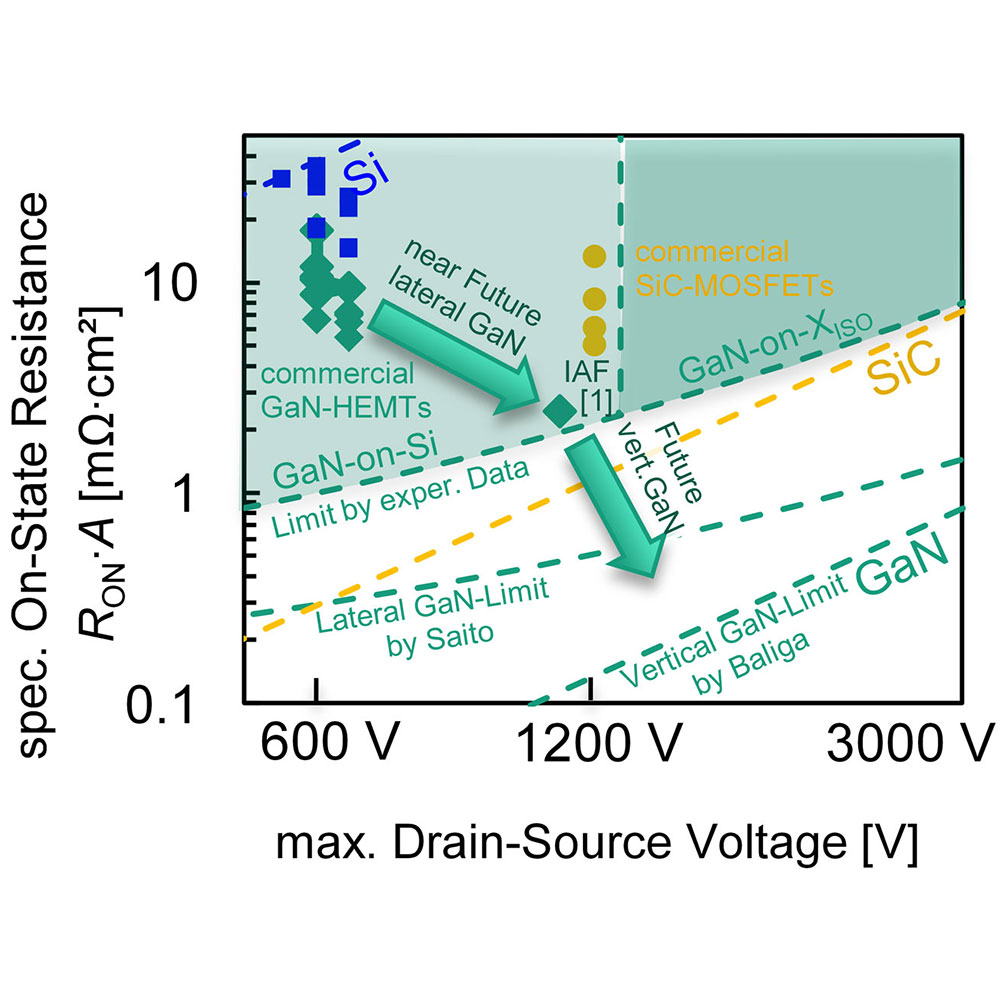

When it comes to components, the trend is toward smaller chips with higher power den-sities and ultrafast switching speeds. Here, the goal is not only increased chip ruggedness at elevated operating temperature ratings; a more significant aim is to deliver outstanding reliability in order to achieve the desired application-specific lifetime. Material science is pivotal to mastering these challenges – with innovative new materials that deliver the nec-essary thermal management, isolation properties, and matching coefficients of thermal expansion. At the PCIM Europe 2024, innovations in this area will include new ceramics and chip passivation materials, as well as new chip bonding technologies, such as advanced soldering or sintering technologies.

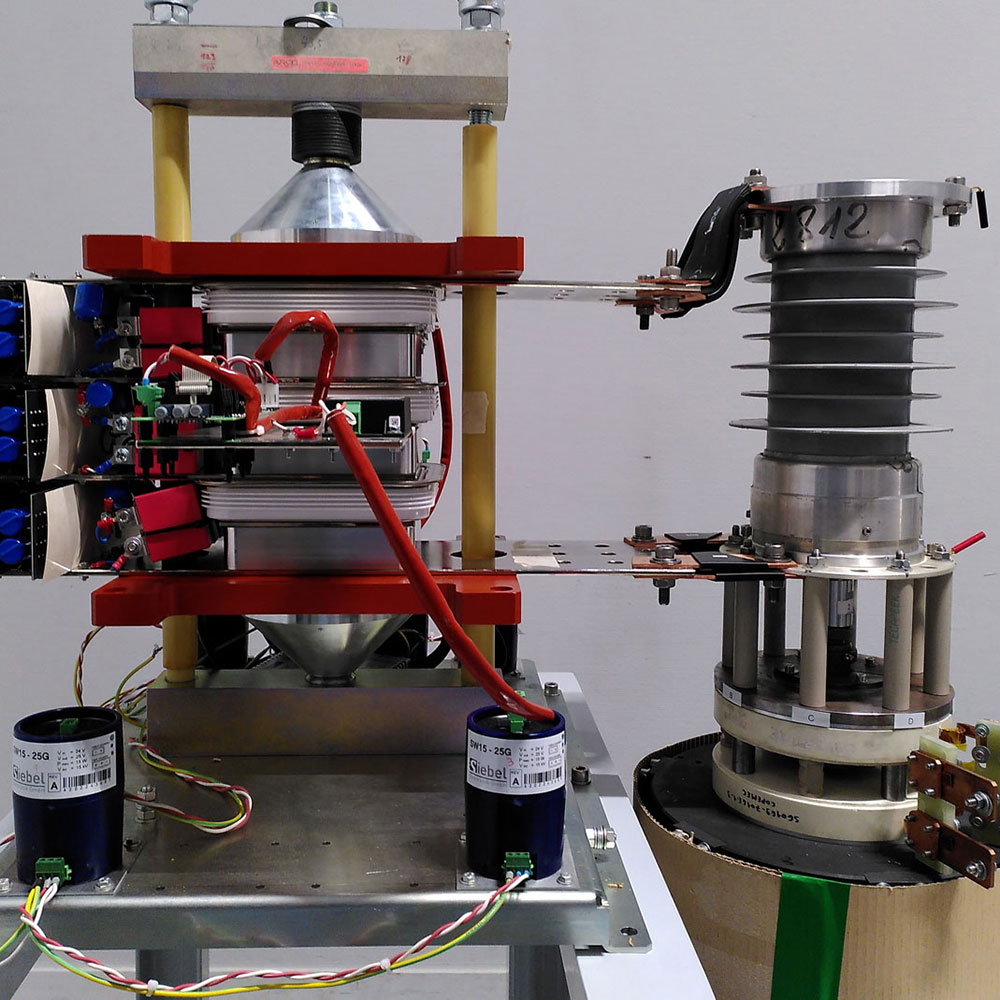

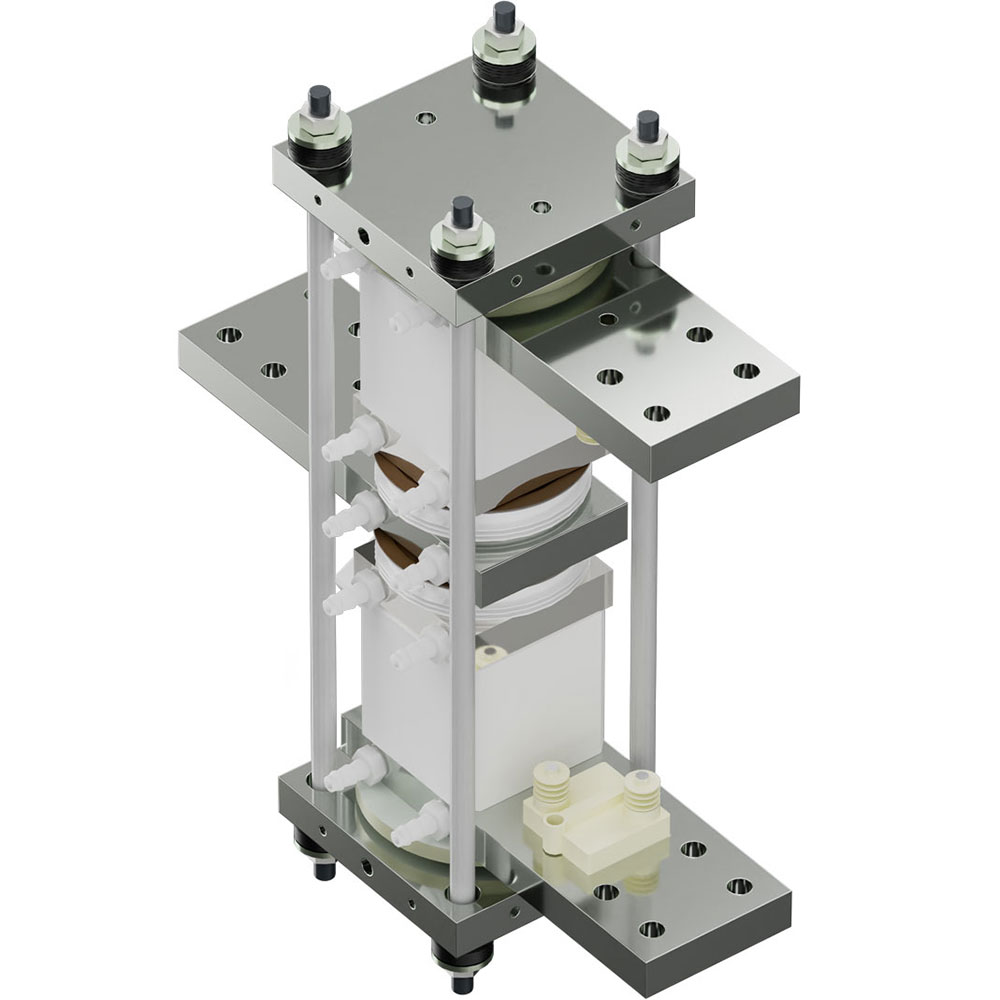

In packaging and interfacing technology, the spotlight is on smart, scalable, power elec-tronic building blocks, or power embedding, which aims to achieve a single, shared platform for power modules that will meet application-specific requirements. Encompassing power chips, integrated sensors, and digital control of power devices, this platform should be scalable in terms of current and voltage ratings. Here, too, module design and material science are key to tackling heat transfer and managing all the parasitics inside the power block. We’ll have several papers about scalable power electronic building blocks, with a focus on establishing new standards and modular-ization. And we’ll show a new approach to designing power modules for the tiny, ultrafast switching WBG (wide bandgap) devices that addresses the many associated challenges.

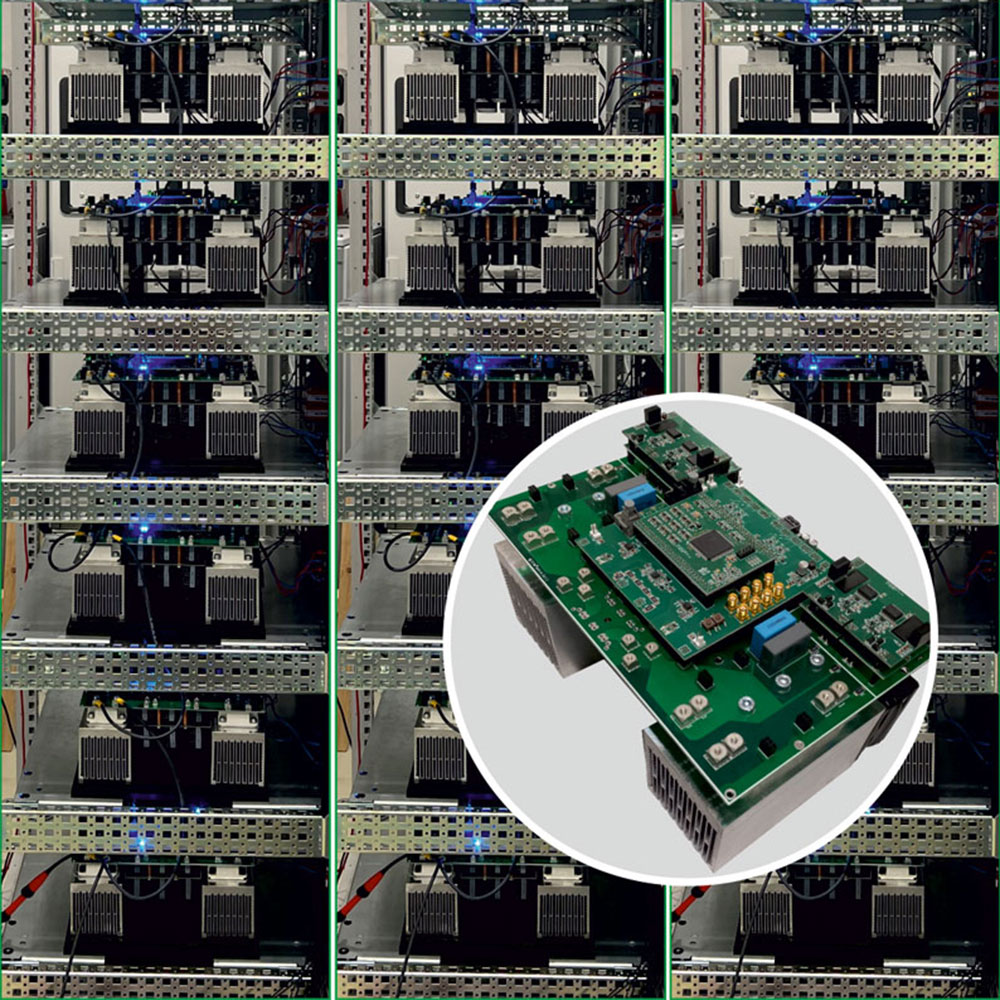

This year’s PCIM Europe highlights the fol-lowing fields of application: the mobility sector, the energy sector, and data centres. In all three fields, there’s a need for more compact power converters operating at high efficiency rat-ings, not least for mobile applications. As with components, increased power densities can pose tough thermal-management challenges – especially in the fastest-growing application area, data centres. Greater efficiency will be key to meeting these demands and ensuring that power converters are reliable and have long useful lifetimes in their widely differing applications and operating environments. We’ll be showing some impressive innovations in the various fields of application – with a particular focus on electromobility.

Interest in AI and its practical applications has grown rapidly in recent years. So, it’s hardly surprising that the technology is becoming in-creasingly important in power electronics. De-ploying AI and digital twins promises shorter development time and faster time-to-market, plus more reliable converter products. During ongoing operations, AI and digital twins will play a central part in predictive maintenance – for example, by helping determine how components are aging. Here, there’s a need for industry standards to gauge the reliability of the vast volumes of data involved. What’s more, we need to think about how the digital world relates to the real world so that we can translate insights from the former to the latter.

One of this year’s keynotes focuses on AI, and we’ll see a good example of how AI is applied in the real-world production of a power converter. We’ll also see the benefits that AI has to offer across the entire product lifecycle – from the initial idea for a new converter, to product development and production, right through to decommissioning.

One of the most important topics for the future is sustainability. Not only are zero carbon emissions a must; we must also significantly reduce the amount of electronic waste, which has risen by 80% in the past decade alone. This will call for a fundamental rethink and a move to a circular economy. Achieving this will entail considering ways of repairing converters and recycling all materials so that we can reuse them. One extremely important factor here will be acquiring the dataset needed to accurately calculate the carbon footprint of components and systems. We also have several papers about design for sustainability, focusing on carbon footprint and lifecycle assessment, with special emphasis on the dataset needed to calculate this footprint and on cost of ownership.