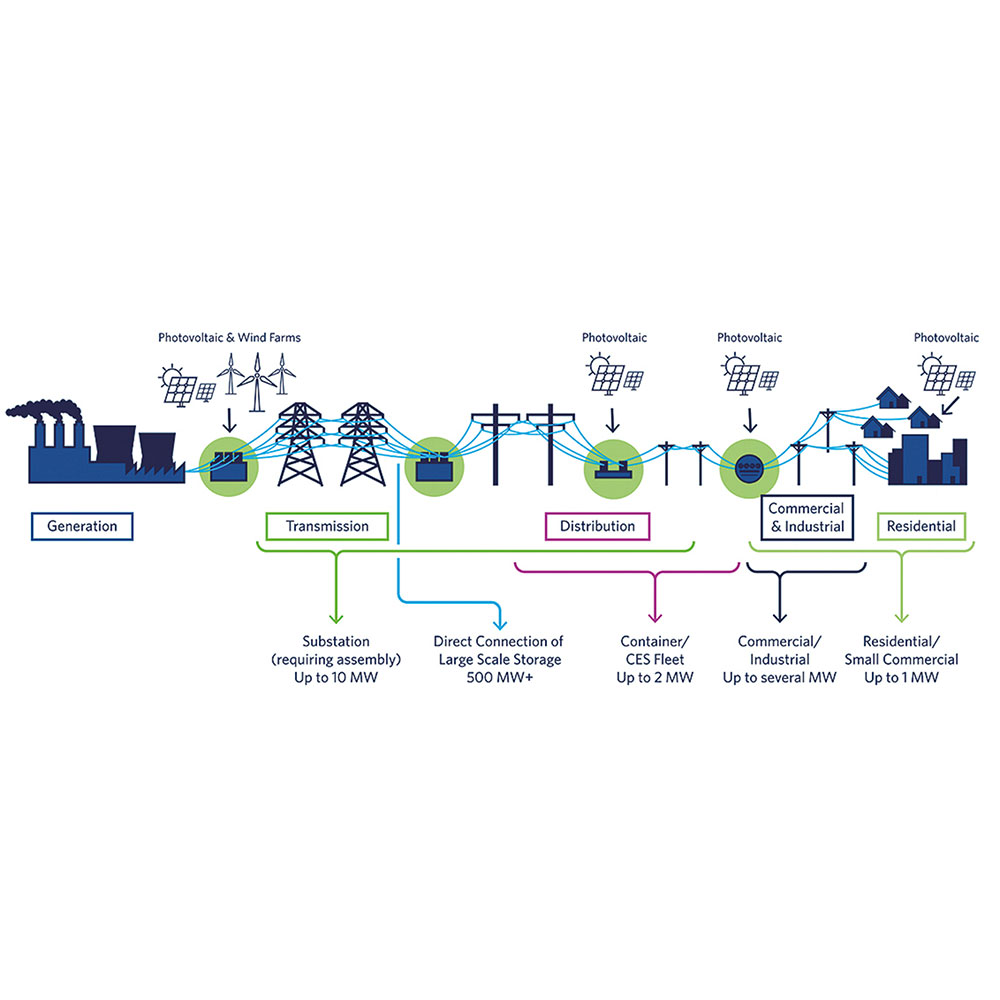

Over 30 years ago, the first ZOPF engineers set out to make energy supply sustainable and fair. Their initial activities in the field of wind energy have developed into a wide range of business areas at several locations in Germany. In addition to the construction and operation of energy parks, the focus has shifted to the manufacture and repair of power electronics.

ZOPF is now in demand worldwide for its range of high-quality power modules, far beyond the original wind energy industry. ZOPF’s focus has remained unchanged: we are contributing to sustainable energy production and helping to shape the defossilisation of the industry.

Busbars (current rails) are required for the manufacture of power electronics. In 2021, the decision was made to take over the previous supplier in southern Germany. Due to increased demand, investments were made in a new production facility. Since January 2025, Europe’s most modern laminating press designed for busbars has been in operation at the new plant in Wickede (Ruhr). In future, busbars up to a size of 1,000 mm x 2,000 mm can be manufactured there under vacuum conditions. In addition to production, ZOPF also supports the development of laminated multi-layer busbars. The company specialises in complex, customer-specific solutions that require secure electrical connections in confined spaces. Its in-house toolmaking facility enables rapid and close communi- cation with the customer’s engineering team. Individual punching, bending, milling and assembly work is carried out in-house.

The cutting of precision-fit insulation films using lasers is also carried out in-house, as is the assembly, pressing and soldering of electrical components on the busbar. The quality standards set in this process are ensured and documented through various testing procedures. ZOPF sources its raw materials in Europe and manufactures exclusively at its own sites in Germany. This guarantees short delivery times and high quality for both large and small series.

At its Leipzig site, ZOPF also develops and manufactures complete power modules and capacitor banks for customers in the aftermarket or for manufacturers of converters and inverters.