By Ole Gerkensmeyer, Vice President EMEA Sales at Nexperia.

These developments are creating a massive demand for efficient, high-voltage-resistant power electronics – primarily based on silicon carbide MOSFETs (SiC MOSFETs) – both in vehicles and in stationary and dynamic charging systems. This article looks at 400V vs. 800V, the high-voltage trend >1,000 V in trucks, MCS and ‘charging while driving’ from an explicit power electronics perspective.

1. System level: 400V vs. 800V vs. >1,000V

Traditional BEV platforms operate with battery voltages around 350–450 V (‘400 V class’). Newer car and truck platforms use 650–920 V (‘800 V class’). For high-power truck charging in the megawatt range, the system is moving towards >1,000 V DC, typically up to 1,250 V (MCS target value).

In terms of power, the following applies:

- 150 kW at 400V → approx. 375A

- 150 kW at 800 V → approx. 188 A

- 1,000 kW at 1,000 V → 1,000 A

- 1,000 kW at 1,250 V → 800 A

Key implications:

- Decreasing currents with increasing voltage: reduced I²R losses, smaller cable cross-sections, smaller busbars and connector systems, less cooling required.

- Scaling to the MW class only becomes practical when system voltages >1,000 V are used; otherwise, currents and material usage explode.

- Higher requirements for insulation, EMC and components: from ~1,000 V, standards for creepage and clearance distances, partial discharge resistance and overvoltage protection become significantly stricter – a playing field for specialised power electronics.

This shifts the ‘competitive arena’ from the infrastructure level to the architecture and component level.

2. Power electronics in vehicles – SiC as an enabler

2.1 800V passenger cars and light commercial vehicles

For passenger cars and light commercial vehicles, the switch from 400 to 800 V in combination with SiC MOSFETs brings key advantages:

Traction inverters

- Higher DC link voltage → lower motor current for the same power, less copper, lower losses.

- SiC MOSFETs enable higher switching frequencies with lower switching losses; filters and magnetic components can be made smaller.

- Higher overall efficiency, especially at high loads (motorway operation), increases range or allows smaller batteries.

On-board charger (OBC)

- 800V batteries require galvanically isolated AC/DC topologies with a high output voltage range.

- SiC enables compact PFC and DC/DC stages with high efficiency over a wide load range – important for bidirectional applications (V2G, V2H).

Auxiliary converters / DC/DC converters

- High-voltage-to-low-voltage DC/DC stages benefit from high switching frequencies and efficiencies, allowing for more flexible vehicle electrical system topologies (12/24/48 V).

- This is creating markets for automotive-qualified SiC modules, gate drivers, reference designs, integrated power stacks and design services for the power electronics industry.

2.2 Trucks and the move to >1,000 V

Battery voltages continue to rise in the heavy-duty sector:

- System voltages of up to 1,250 V DC are planned in order to deliver 1 MW via CCS successors or MCS.

- On the vehicle side, this means that traction inverters, DC/DC stages and charging interfaces must be designed for these voltages.

SiC MOSFETs are even more prevalent here than in the passenger car sector:

- Classic Si IGBTs reach their thermal and switching limits at the required voltage and power densities.

- SiC components allow for 1.2 kV and 1.7 kV classes, which are designed for >1,000 V systems, while offering high switching frequencies and efficiency.

For truck OEMs and their suppliers, development tasks are shifting towards:

- Highly integrated, liquid-cooled high-voltage power stacks (traction + DC/DC + charger in common HV domains).

- Functional safety (ISO 26262) and insulation coordination in >1,000 V environments.

- Standardised interfaces to the MCS system (communication, protection concepts, diagnostics).

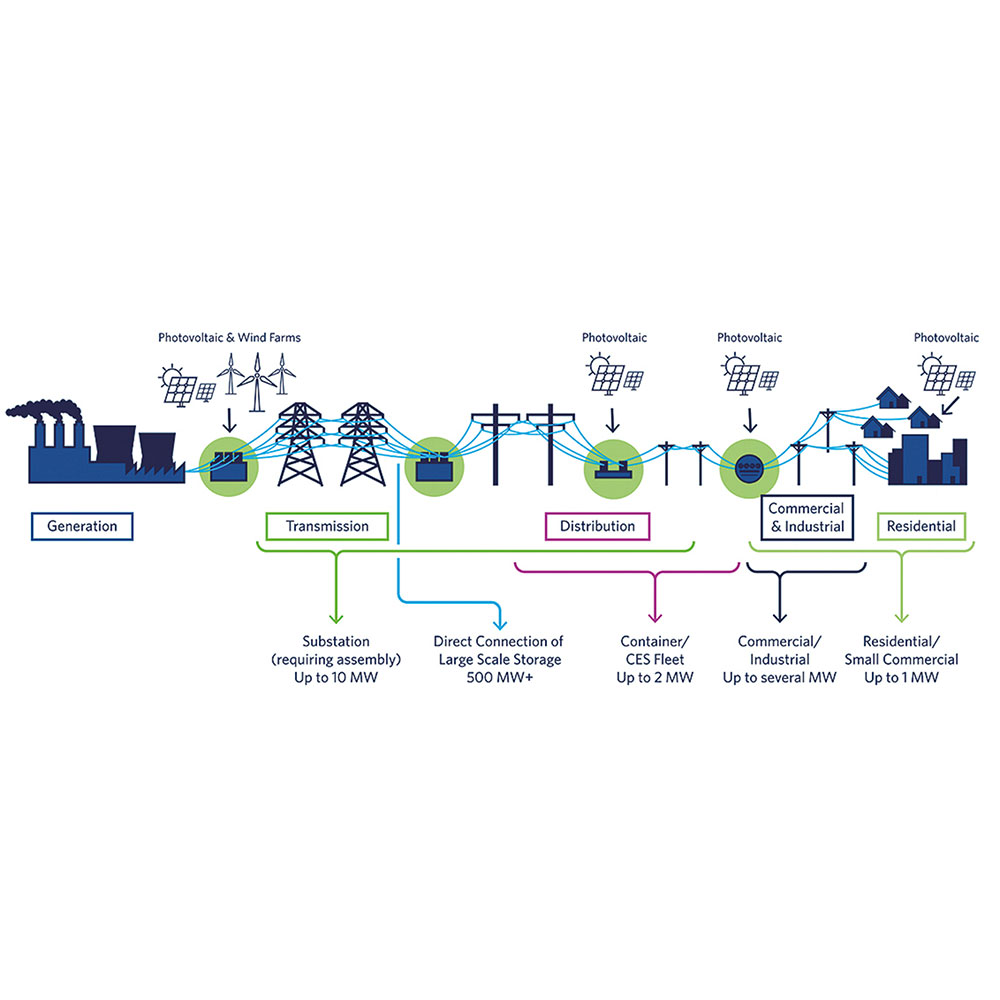

3. Charging infrastructure: HPC today, >1,000 V MCS tomorrow

3.1 HPC network (up to ~1,000 V)

Across Europe – particularly in Germany – HPC locations with 150–400 kW per charging point have become established. Most systems support output voltages of up to around 800–1,000 V.

Power electronics opportunities:

- Modular AC/DC front ends and DC/DC modules (e.g. 30–75 kW) based on SiC, which can be scaled to 150–400 kW systems.

- Standardised ‘power building blocks’ for different operator concepts (single column, charging park, truck hub).

- Intelligent load management and grid support functions (reactive power provision, grid support, local storage integration).

3.2 Megawatt Charging System (MCS) – >1,000 V for trucks

The MCS is explicitly aimed at the megawatt class in long-distance truck transport. It is designed for:

- System voltages up to approx. 1,250 V DC

- Currents up to 3,000 A

- Power outputs from 1–3 MW.

This makes >1,000 V charging systems for trucks the new standard in the upper power class. From a power electronics perspective, this means:

Topologies

- Multi-level converters between the medium-voltage grid and ~1,250 V DC intermediate circuit (e.g. modular multilevel converters).

- Isolated DC/DC stages close to the vehicle connection, optimised for high current carrying capacity and dynamic load profiles.

Components and modules

- 1.2–1.7 kV SiC modules in parallel connection, with low stray inductance and optimised cooling.

- High-performance gate drivers with protection functions (desaturation, Miller clamp, active current limiting).

System aspects

- Grid compatibility with highly fluctuating loads in the MW range.

- High demand for condition monitoring and predictive maintenance due to high utilisation of the sites.

The ongoing MCS pilot projects show that >1,000 V systems are technically manageable in real-world operation – but they also present the industry with new requirements in terms of design, standards and field support.

4. Regulatory framework: AFIR & Co. – Voltage-agnostic, performance-driven

The European AFIR and national regulations (LSV, MessEG/MessEV, VDE application rules) specify minimum performance and densities for charging infrastructure, but do not explicitly distinguish between 400, 800 or >1,000 V. The decisive factors are:

- Total power output per location (HPC hubs for cars, multi-MW hubs for trucks)

- Availability, interoperability and transparent billing

- Grid compatibility and compliance with electrical limits

For the power electronics industry, this means that competitive advantages arise from highly integrated, standard-compliant converter platforms that can be rolled out across multiple voltage and power classes – from 400 V passenger car HPC to >1,000 V MCS truck hubs.

5. Dynamic inductive charging (‘charging while driving’)

Dynamic inductive charging on motorways complements stationary systems:

- Coils integrated into the road surface transfer energy contactlessly to passing vehicles (cars or trucks) with specially equipped receiver coils.

- Individual coil segments each deliver a defined power output (e.g. in the double-digit kW range); the effective charging power is determined by segment density, driving speed and the proportion of electrified track.

Power electronics perspective:

- High-frequency resonant converters (typically several 10 kHz) with precise power control.

- SiC MOSFETs are ideal for high frequencies, high efficiency and compact coil drivers.

- Strict EMC requirements (fields in close proximity to passengers, radio services and vehicle electronics).

- In Germany, pilot routes (such as on the A6 motorway in Bavaria) show that such systems are technically feasible; however, they are not yet standardised for industrial use. In the long term, they could primarily supplement high-load corridors and relieve stationary charging hubs – again with a high proportion of power electronics innovation.

6. Markets and opportunities for power electronics

In summary, clear market segments are emerging along the voltage levels:

- 400 V world: Retrofit and cost optimisation, Si-based with gradual transition to SiC in critical paths.

- 800 V world: Growth area in the passenger car and light commercial vehicle segment; SiC MOSFETs and modules are becoming the de facto standard in traction, OBC and DC charging paths.

- >1,000 V world (MCS, truck hubs): High-end segment with high barriers to entry, strong focus on 1.7 kV SiC technologies, complex converter topologies and close coupling to grid operators.

Cross-cutting issues:

- Packaging innovations (sinter-based connection technology, optimised heat sinks, double-sided cooling, embedding of bare-die chips in printed circuit boards).

- Standards and certifications (automotive qualification, grid codes, safety standards).

- Digital services (monitoring, predictive maintenance, OTA updates of converter firmware).

This presents key opportunities for European suppliers who deliver not only components but also complete, scalable system platforms.

7. Conclusion

The development of 400 to 800 V and further to >1,000 V charging systems for trucks is less a question of the plug and more a question of the power electronics architecture:

- 800 V passenger car and >1,000 V truck systems (MCS) require highly efficient, compact converters – increasingly based on SiC MOSFETs.

- The public infrastructure in Europe is already largely 800 V-capable; the next technological leap is taking place in the background: in high-voltage modules, topologies, control systems and network interfaces.

- Dynamic charging while driving adds another element to this landscape that is strongly driven by power electronics.

- This makes it clear that anyone investing today in wide bandgap power electronics, >1,000 V system design, packaging and grid integration is positioning themselves precisely where the added value of electromobility will be created in the next decade – in the ‘invisible’ layers behind plugs, cables and asphalt. eg